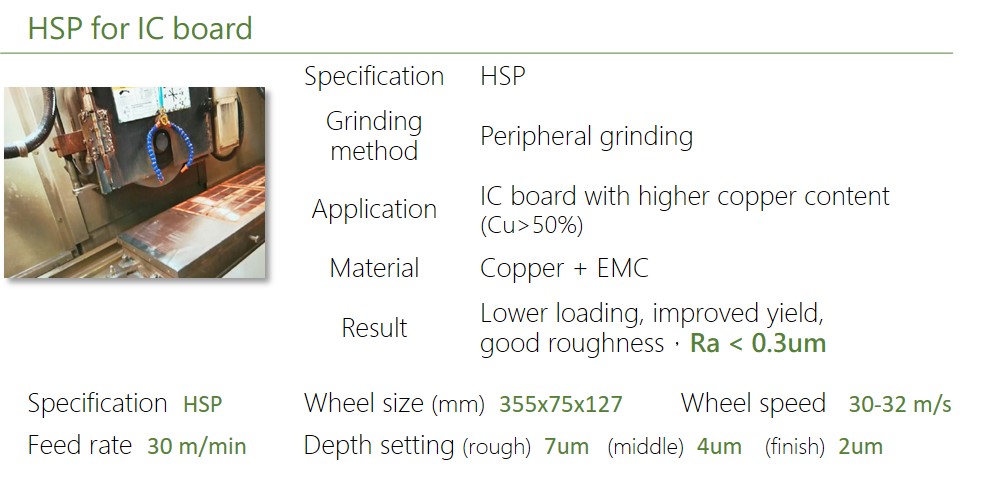

IC board could be divided into ABF, BT and MIS by the materials and process. Part of the process is based on epoxy resin as the main sealing film material, and with the copper wires which are electroplated to build on each molding layer (the figure shown as below). Therefore, the grinding wheel will simultaneously grind both epoxy resin and copper wires in the grinding process.

In addition to the grinding process of the above-mentioned substrate manufacturing. HSP wheel also provides the best solutions for the application grinding process of EMC packaging (Epoxy Molding Compounds), PLP panel level packaging, FOPLP, and engineering plastic materials such as PEEK (polyetheretherketone) and PPS (polyphenylene sulfide) grinding.

Current processing experience includes : Pure cooper, Cooper + EMC, ABF + cooper, BT + cooper, EMC + Chip, Invar, PEEK, PPS and so on.

Anchor provides two solutions of Vitrified finishing wheel and HSP wheel, according to the copper content of work piece and roughness requirement.