Super Abrasive Tools – Introduction of Diamond and CBN Tools

Description of Diamond Tools

The use of a bonding will fix diamond powder (or CBN powder) which is a summary of diamond abrasion wheel and diamond grinding wheel.The grinding tools made by diamond and CBN abrasives.

The Subjects of Material for Diamond Tools

Diamond

Tungsten Carbide

Carbide Tool

Ceramics

Cast Iron

Ferrite

Glass, Reinforced Glass Fiber

Quartz, Silicon, Crystal, Gem

Stones

Cement, Concrete, Asphalt

Tile

Plastics, Rubber

Asbestos, Refractory Material

Cubic Boron Nitride (CBN)

High Speed Steel

Tool Steel

Alloy Tool Steel

Bearing Steel

Stainless Steel

Chromium Steel

Heat-treated Steel

Special Alloy Steel

Heat-Resisted Steel

Special Cast Iron

Alnico

Inconel

Ti-Alloy

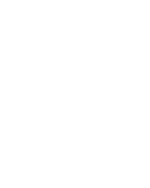

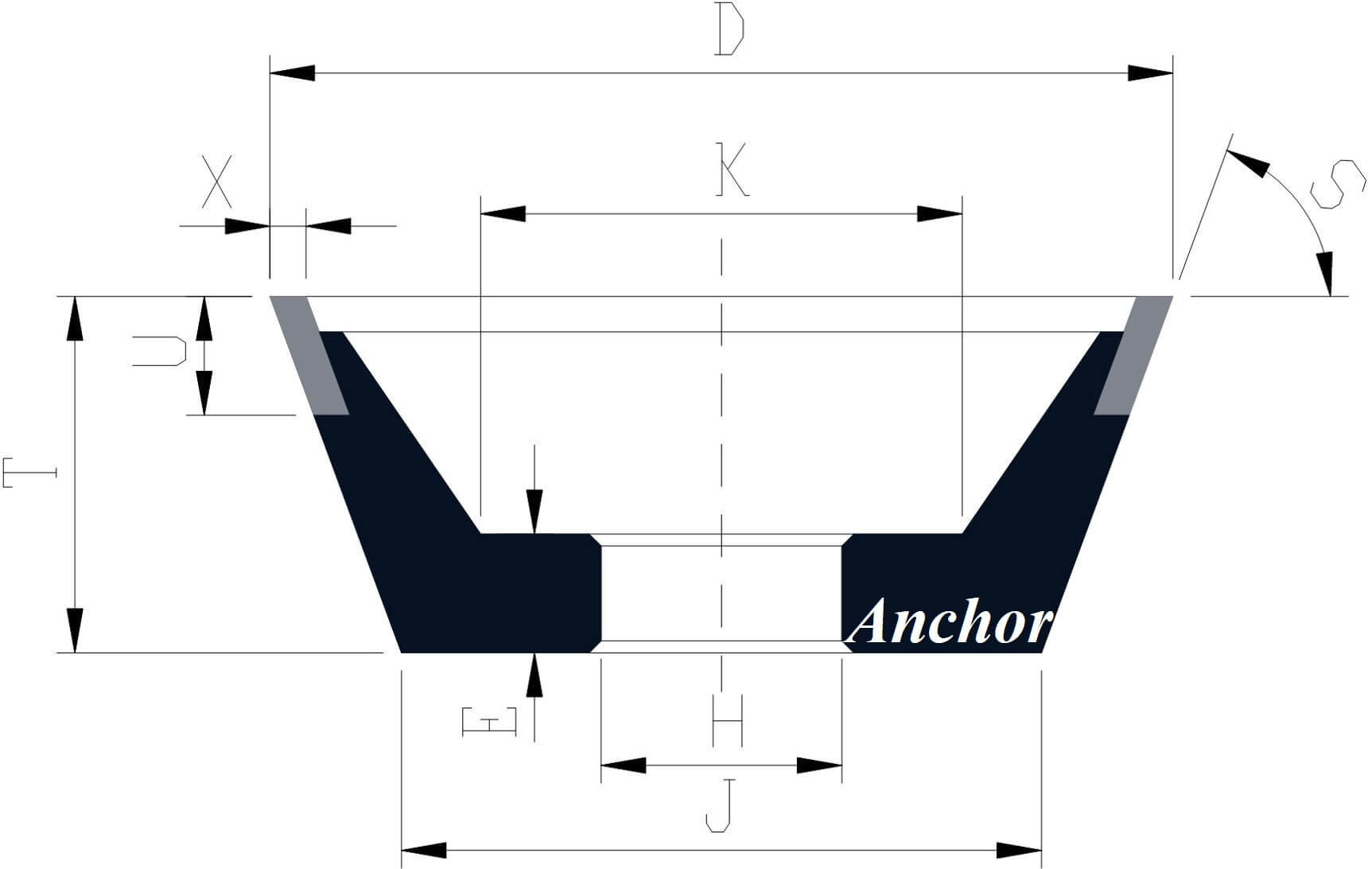

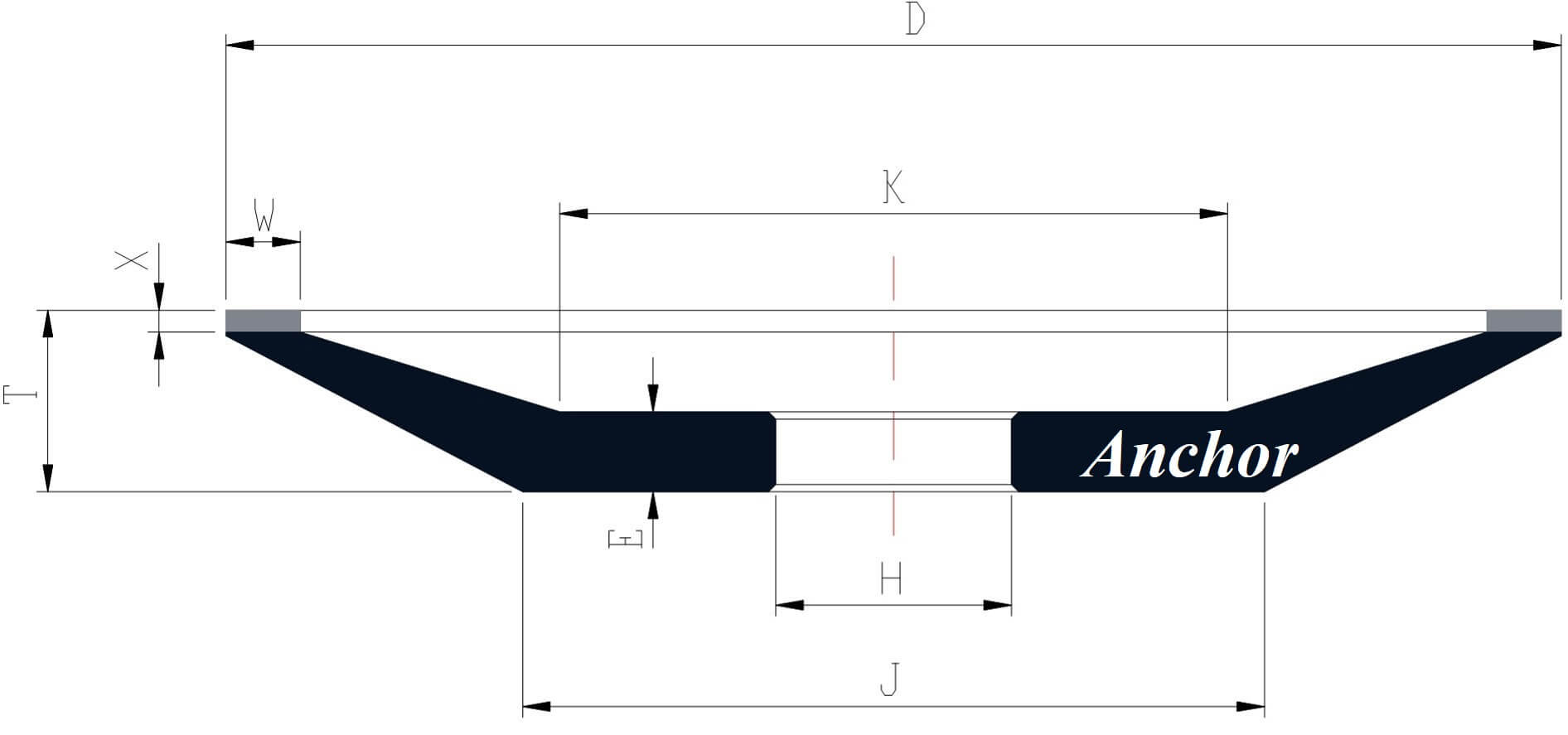

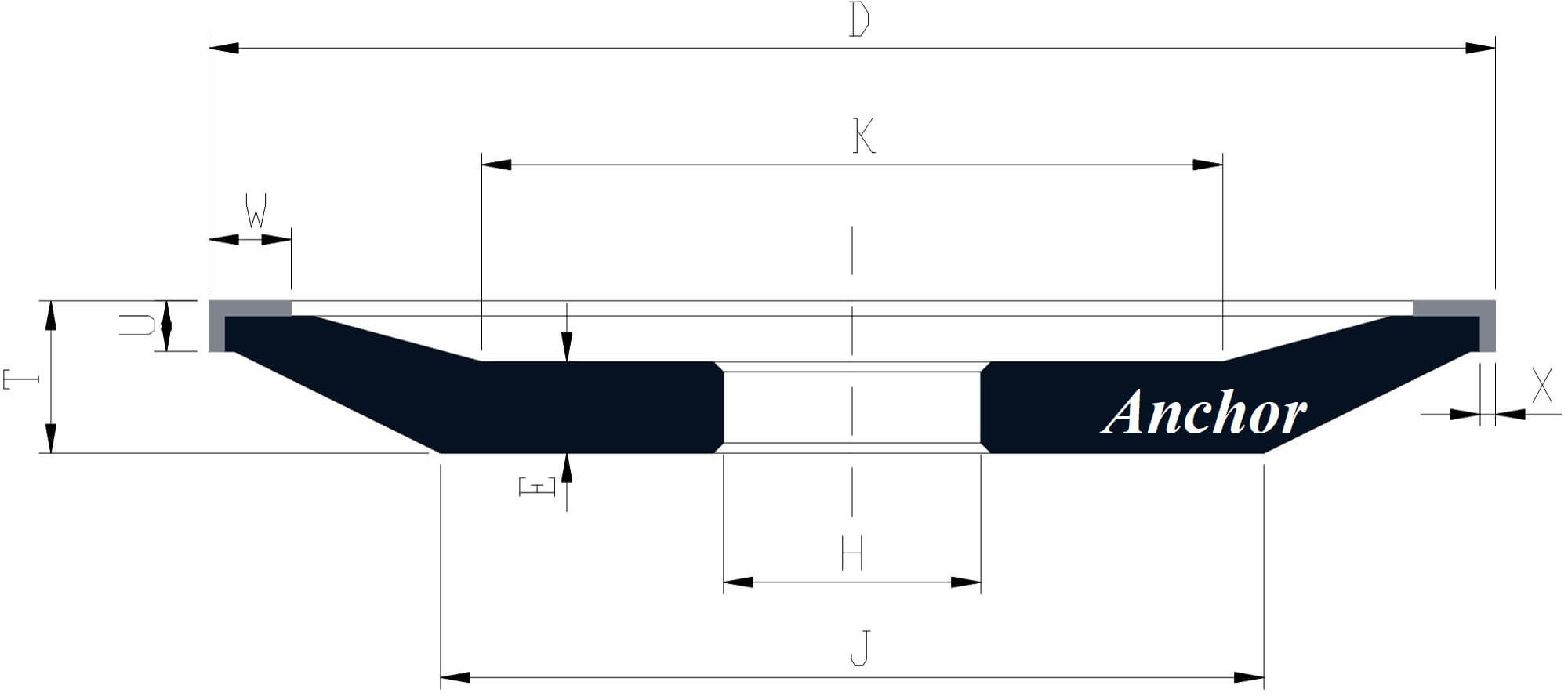

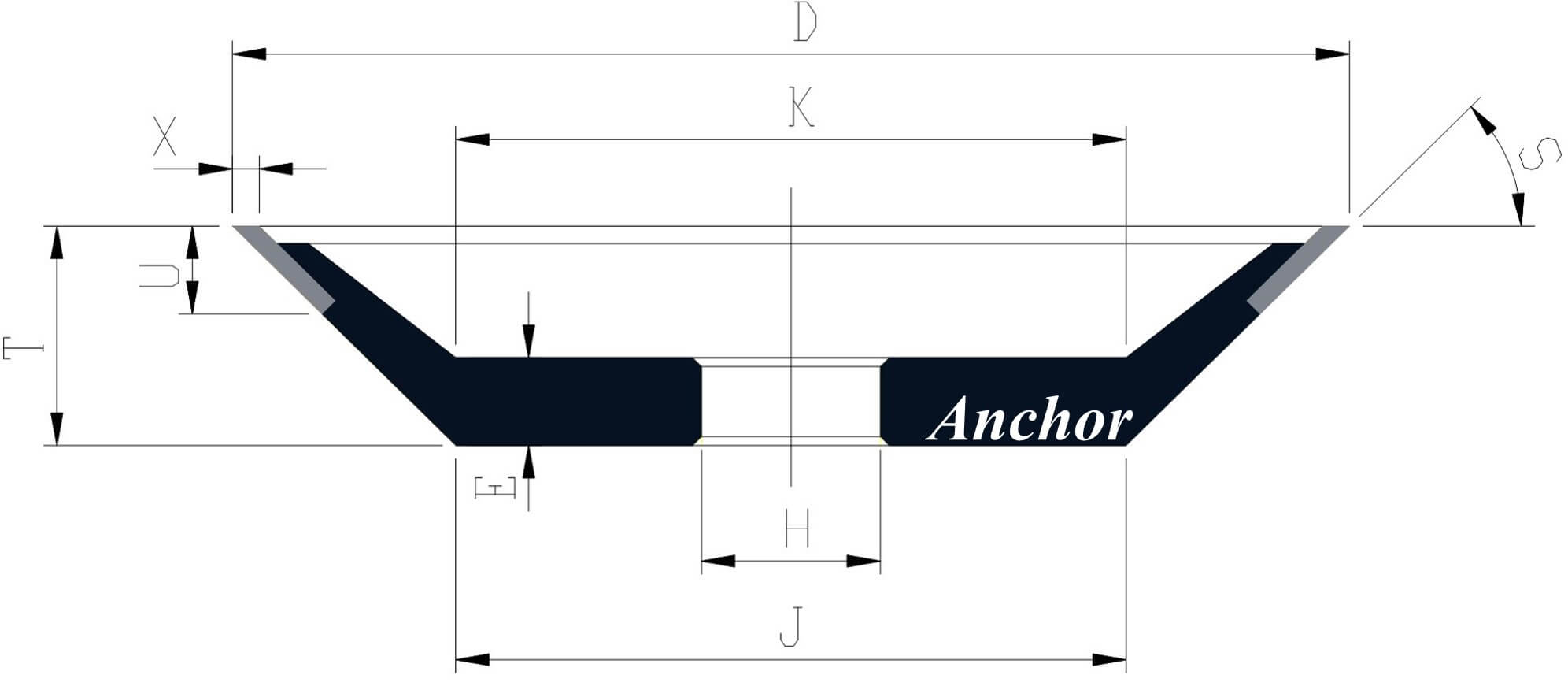

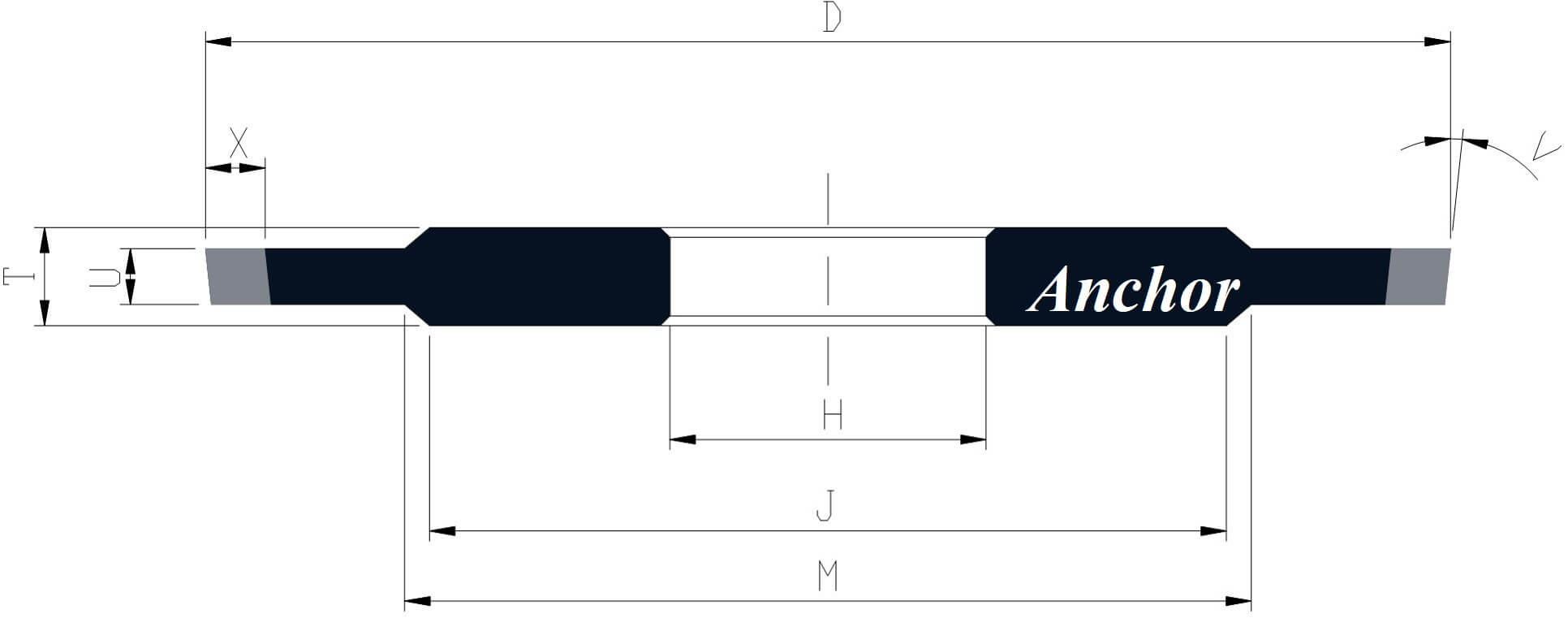

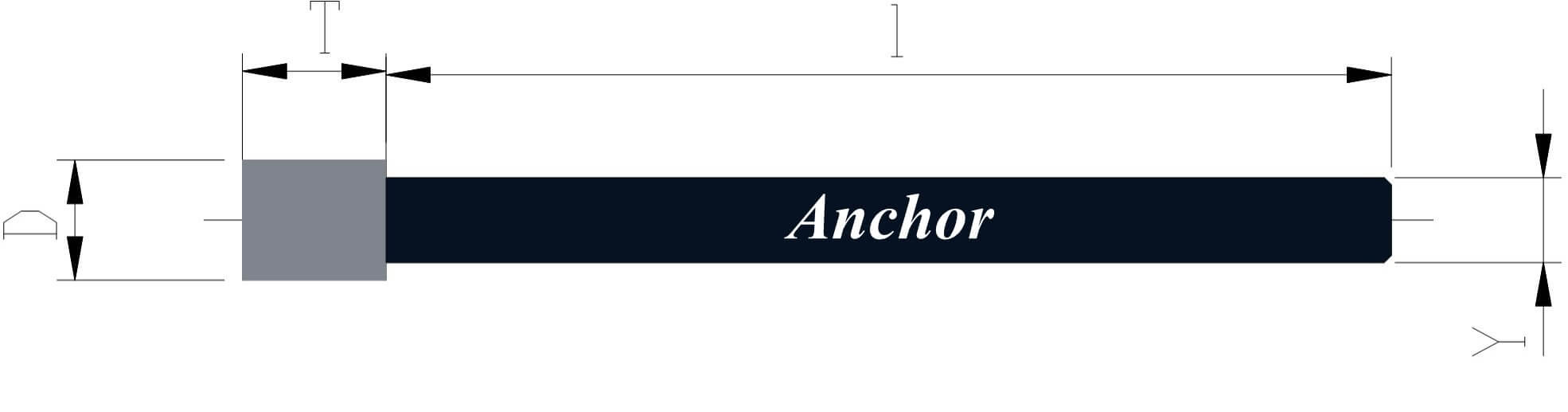

Ordering Information: Specification and Size

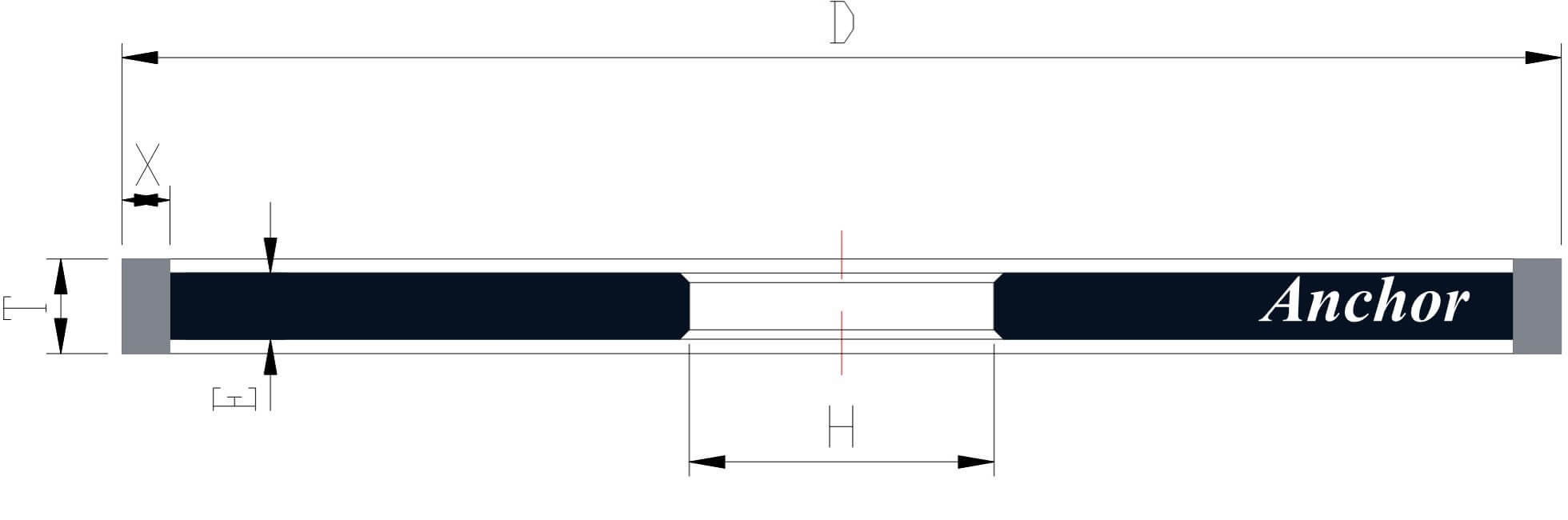

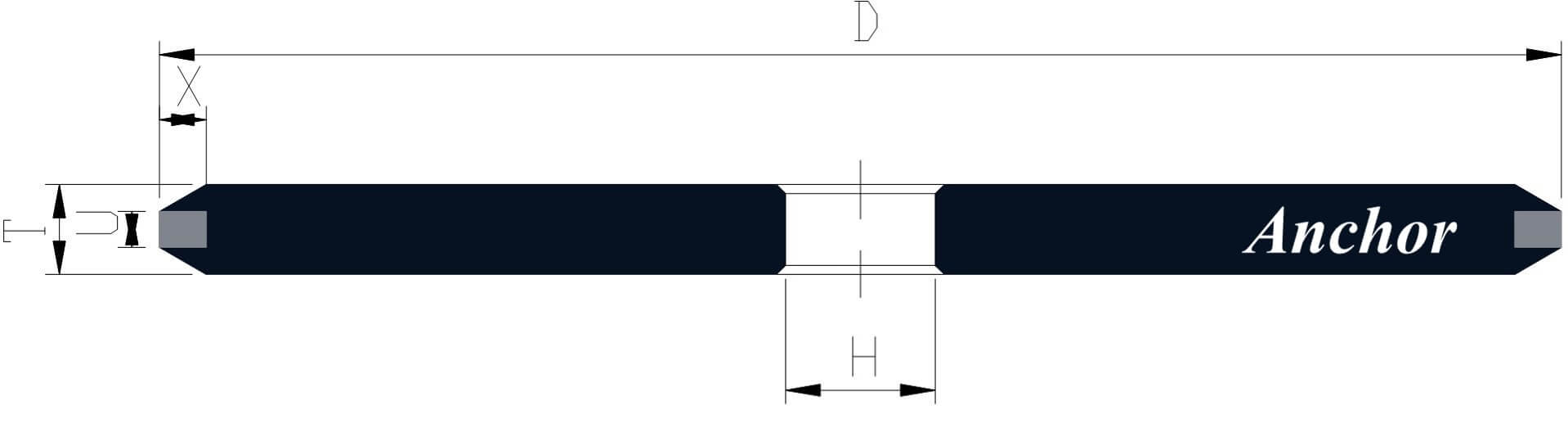

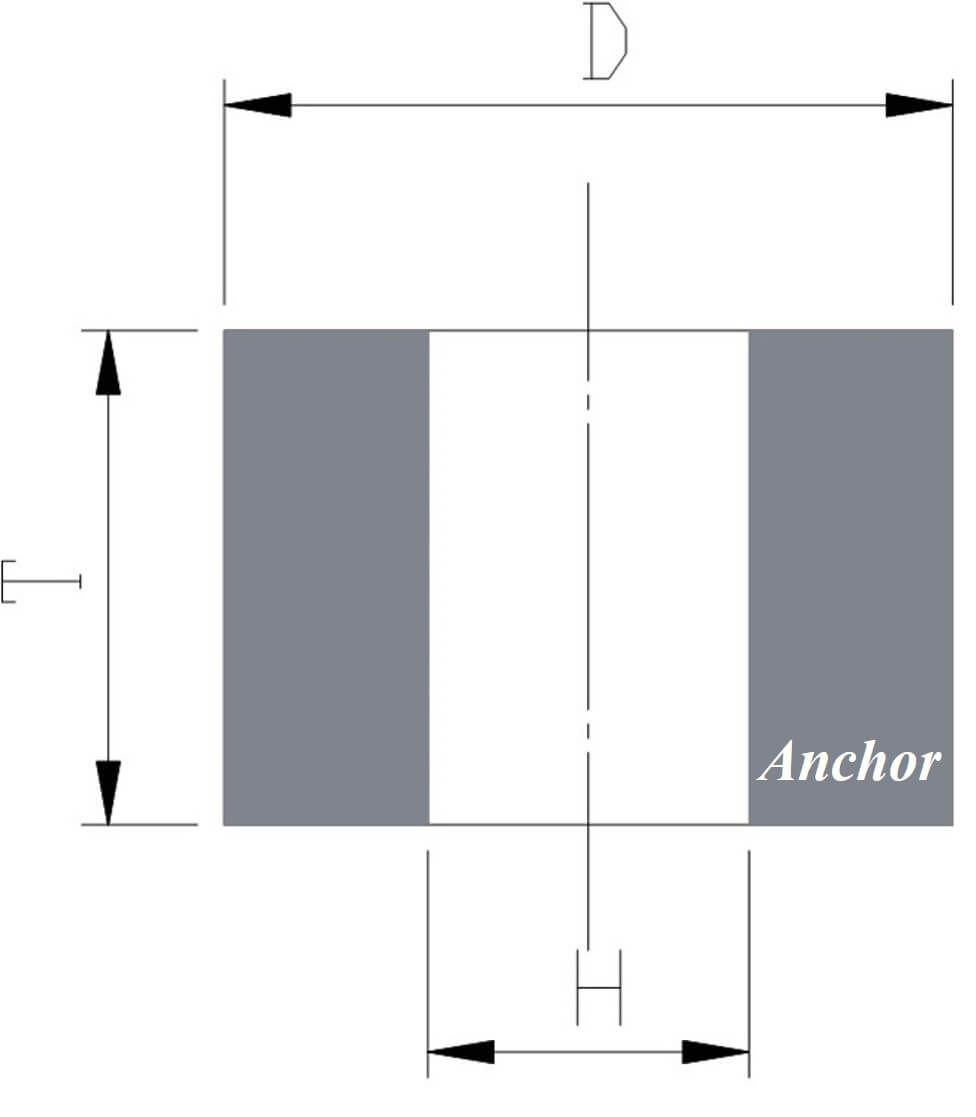

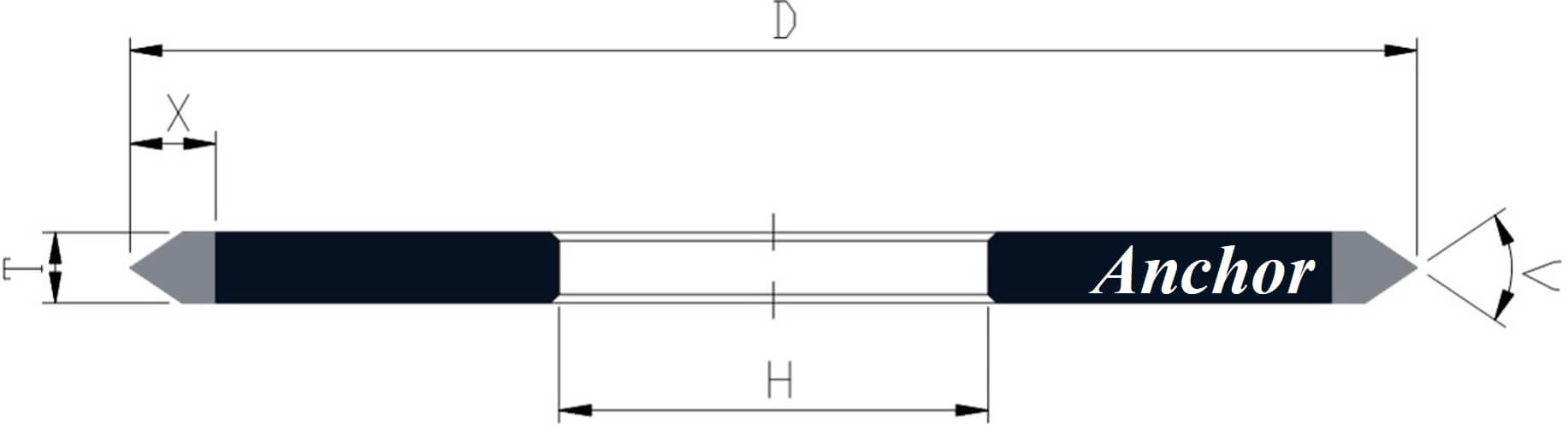

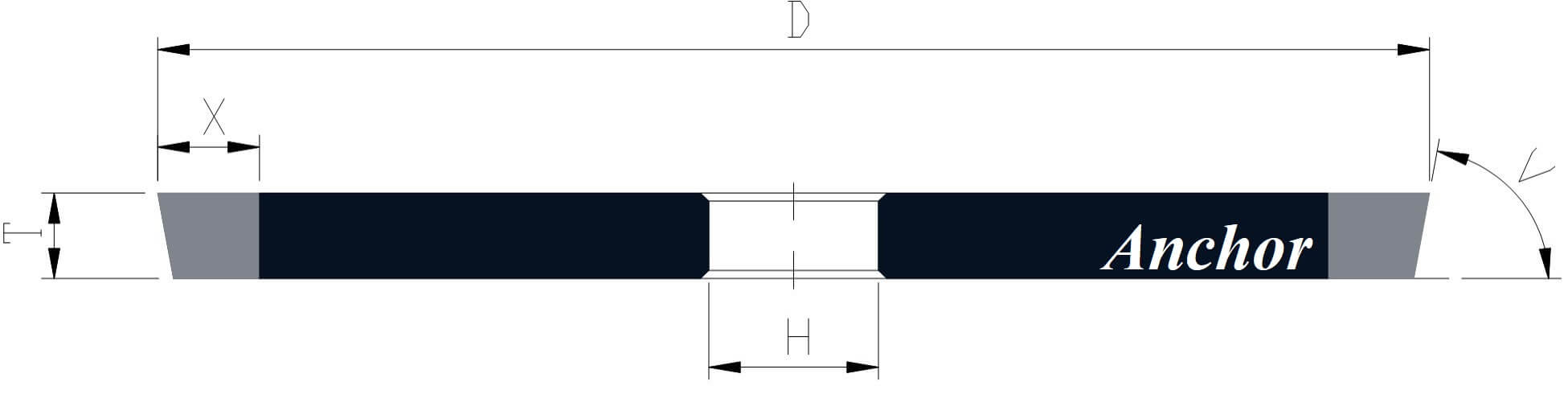

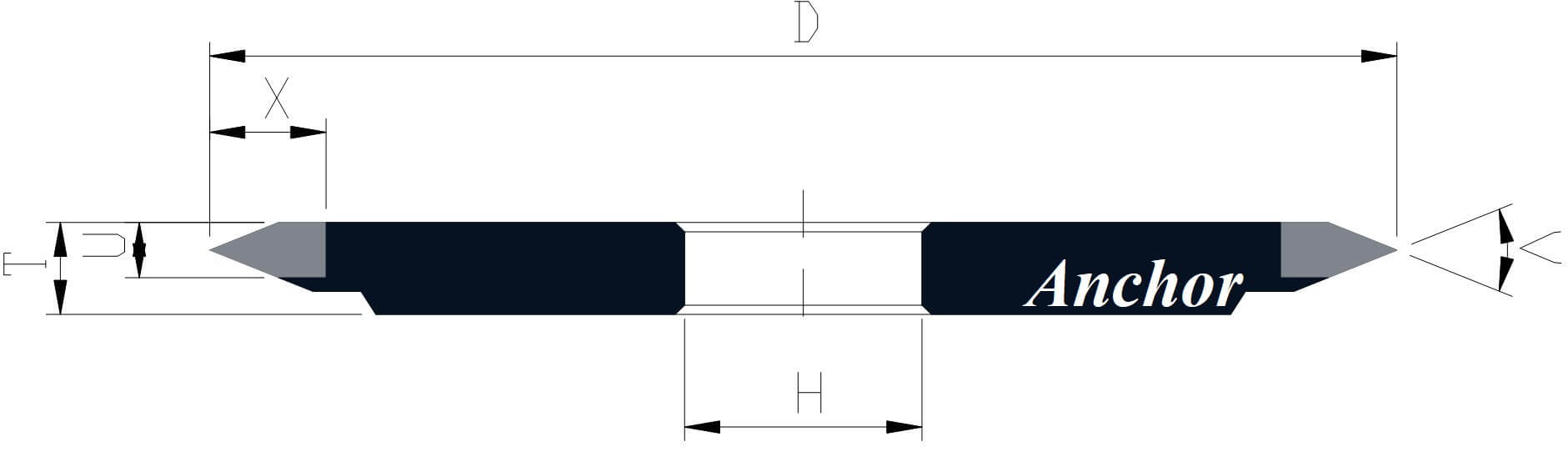

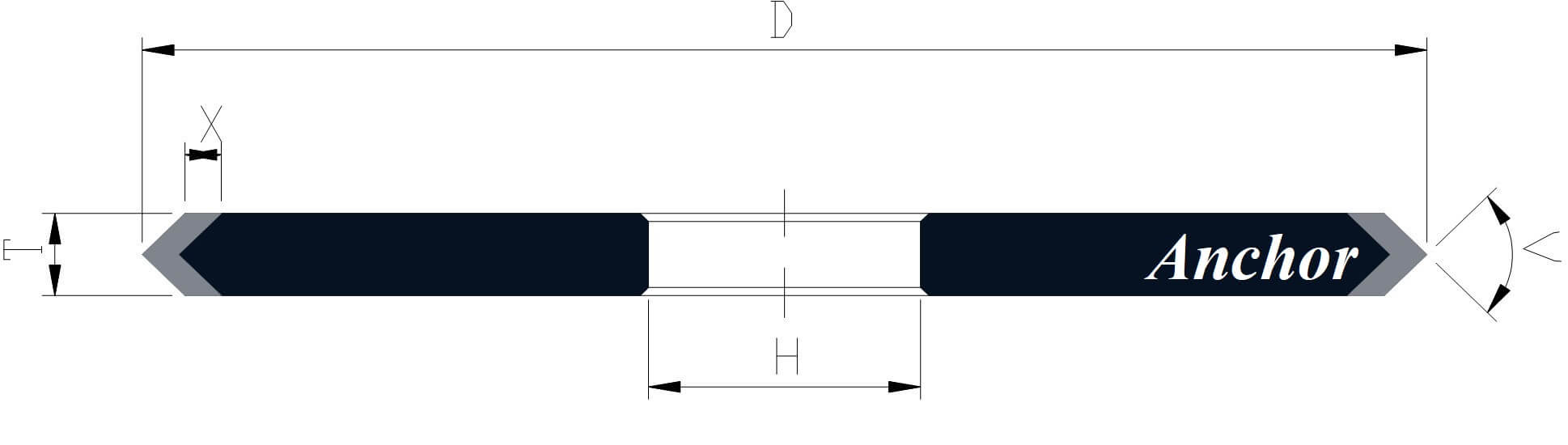

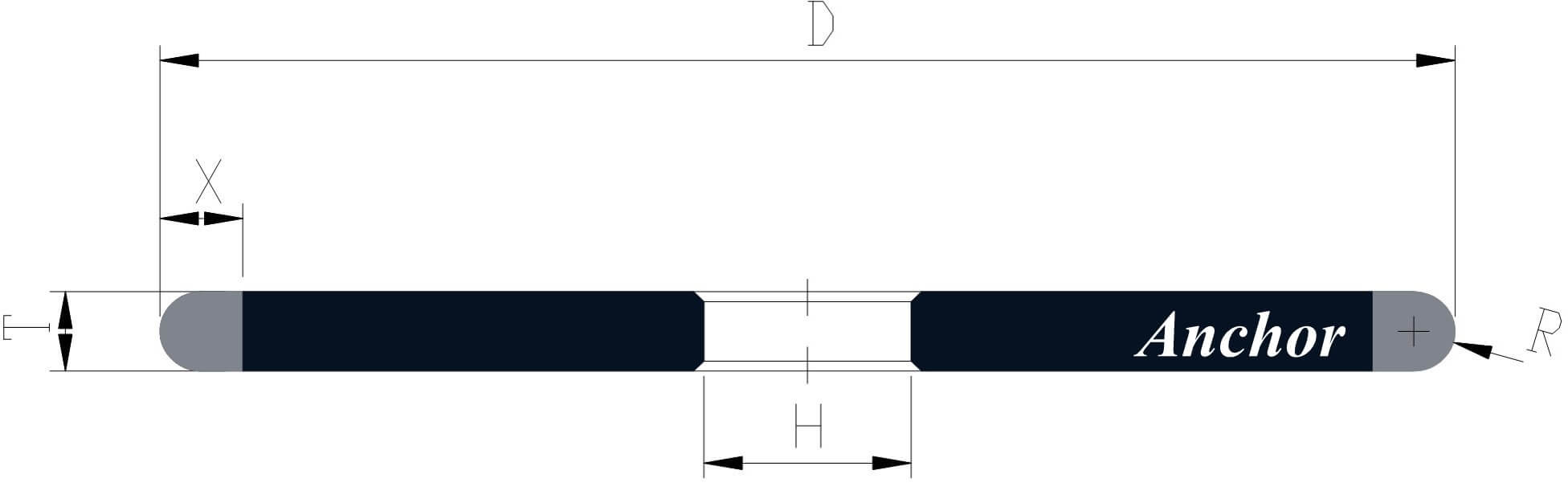

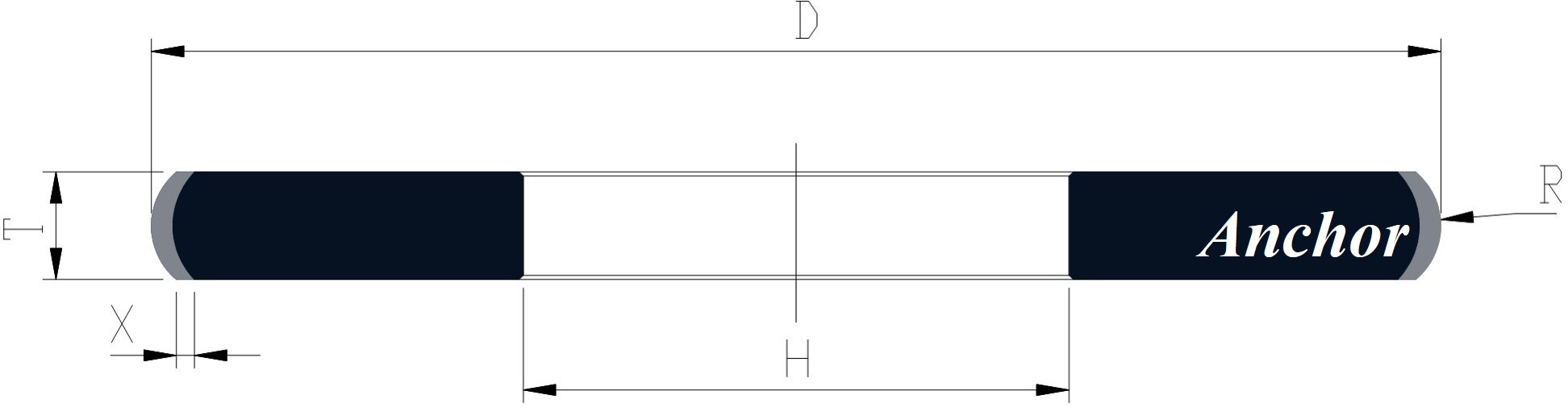

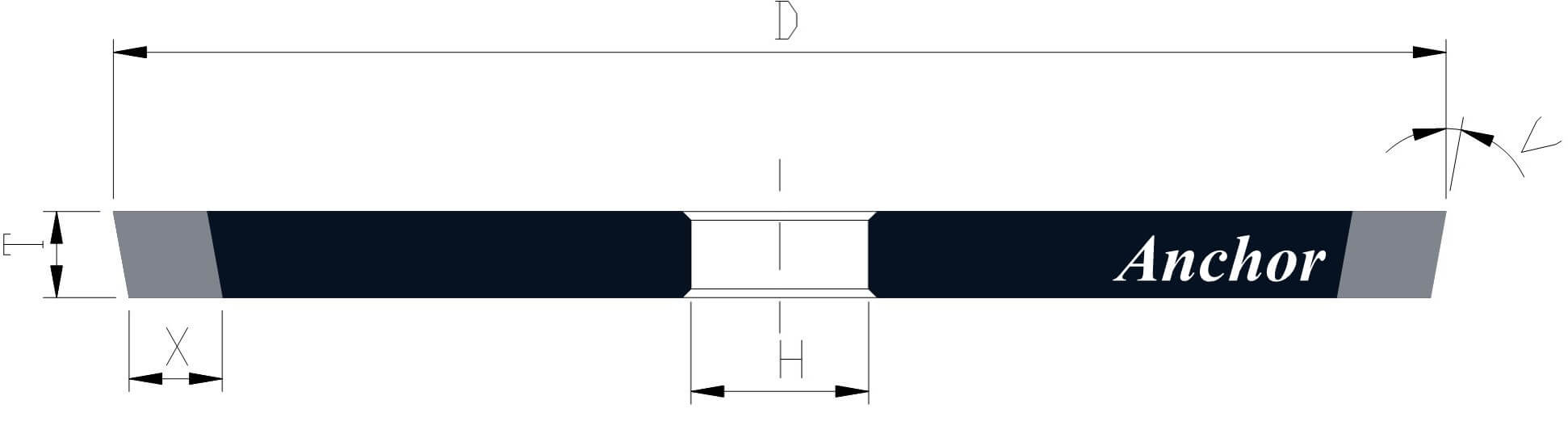

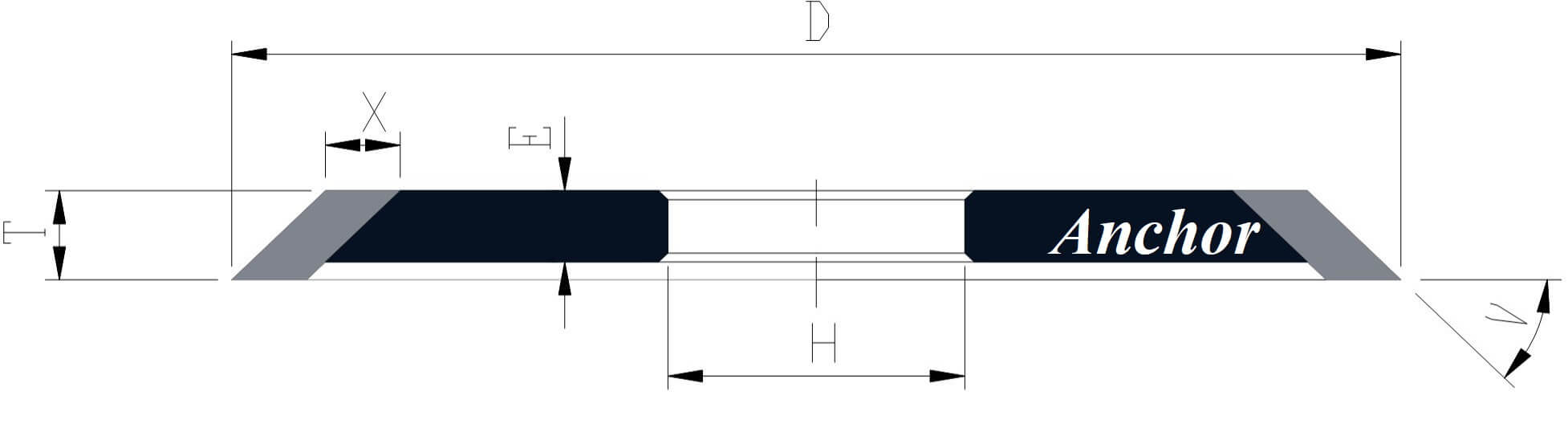

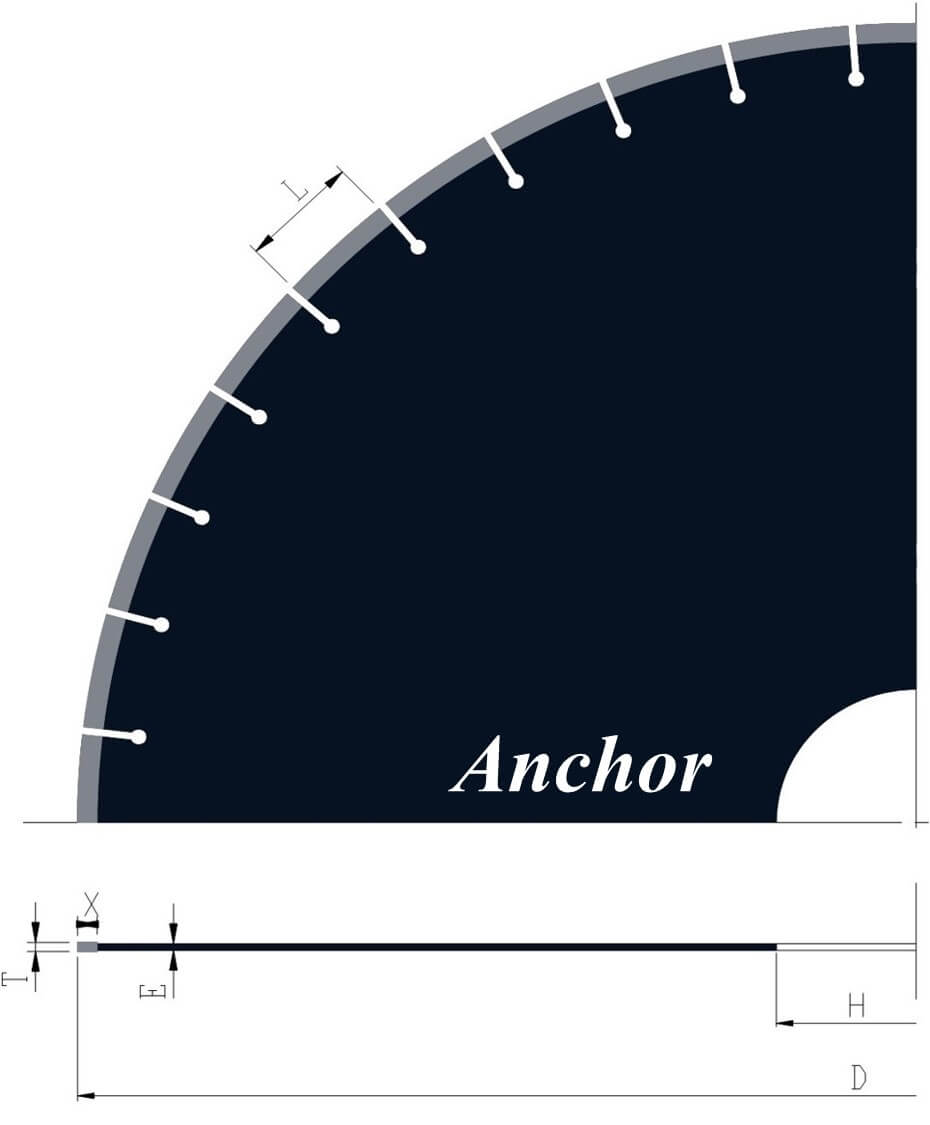

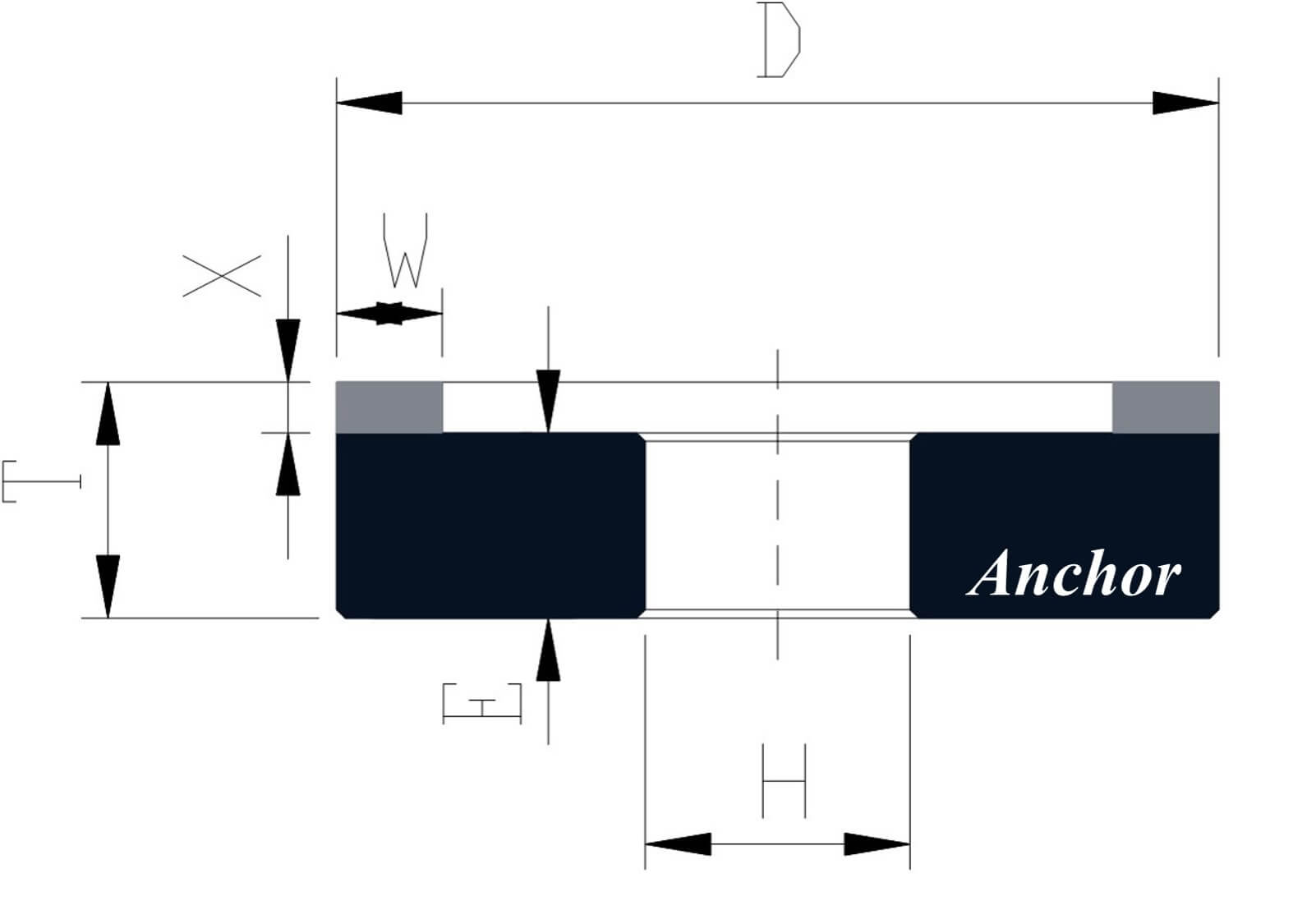

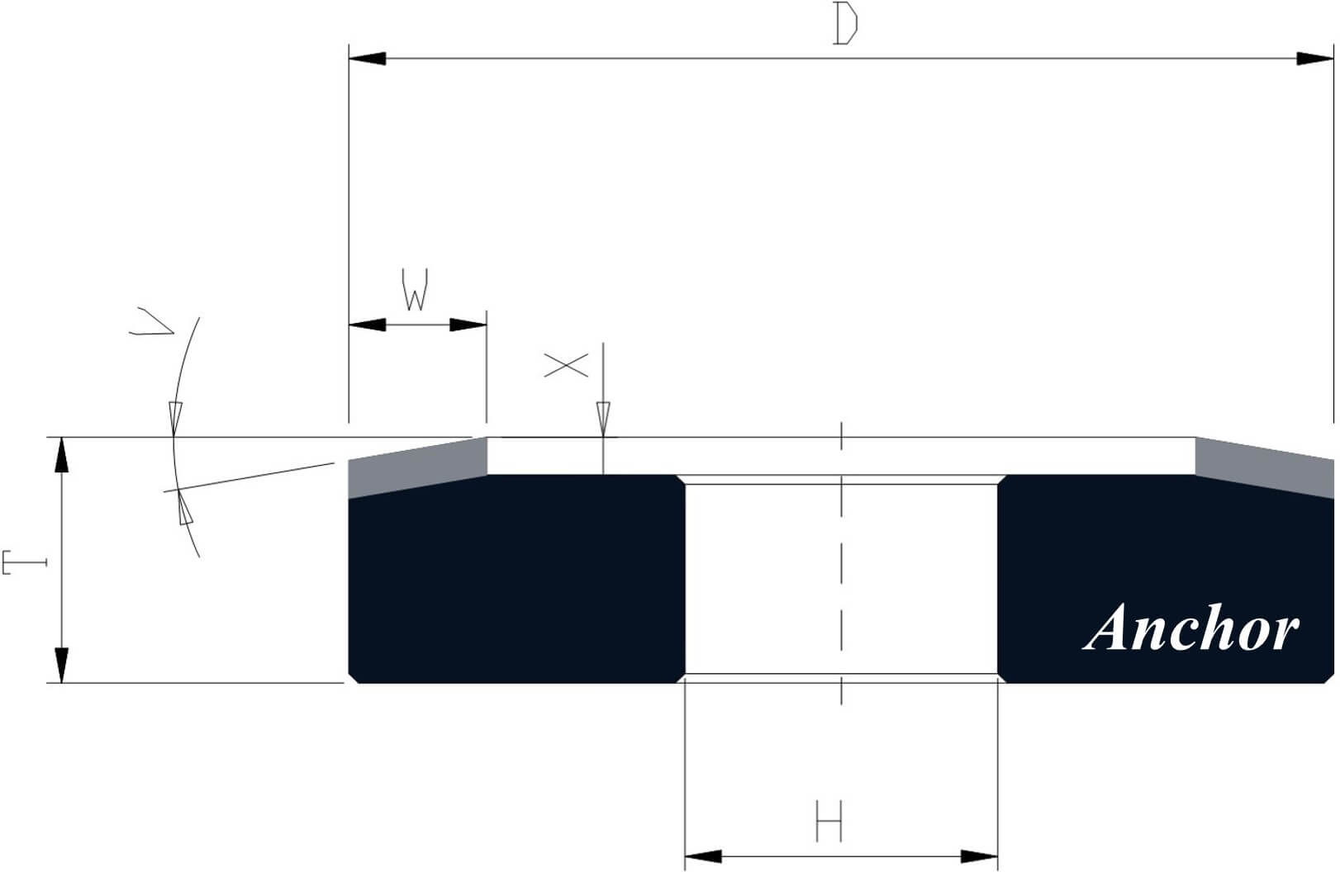

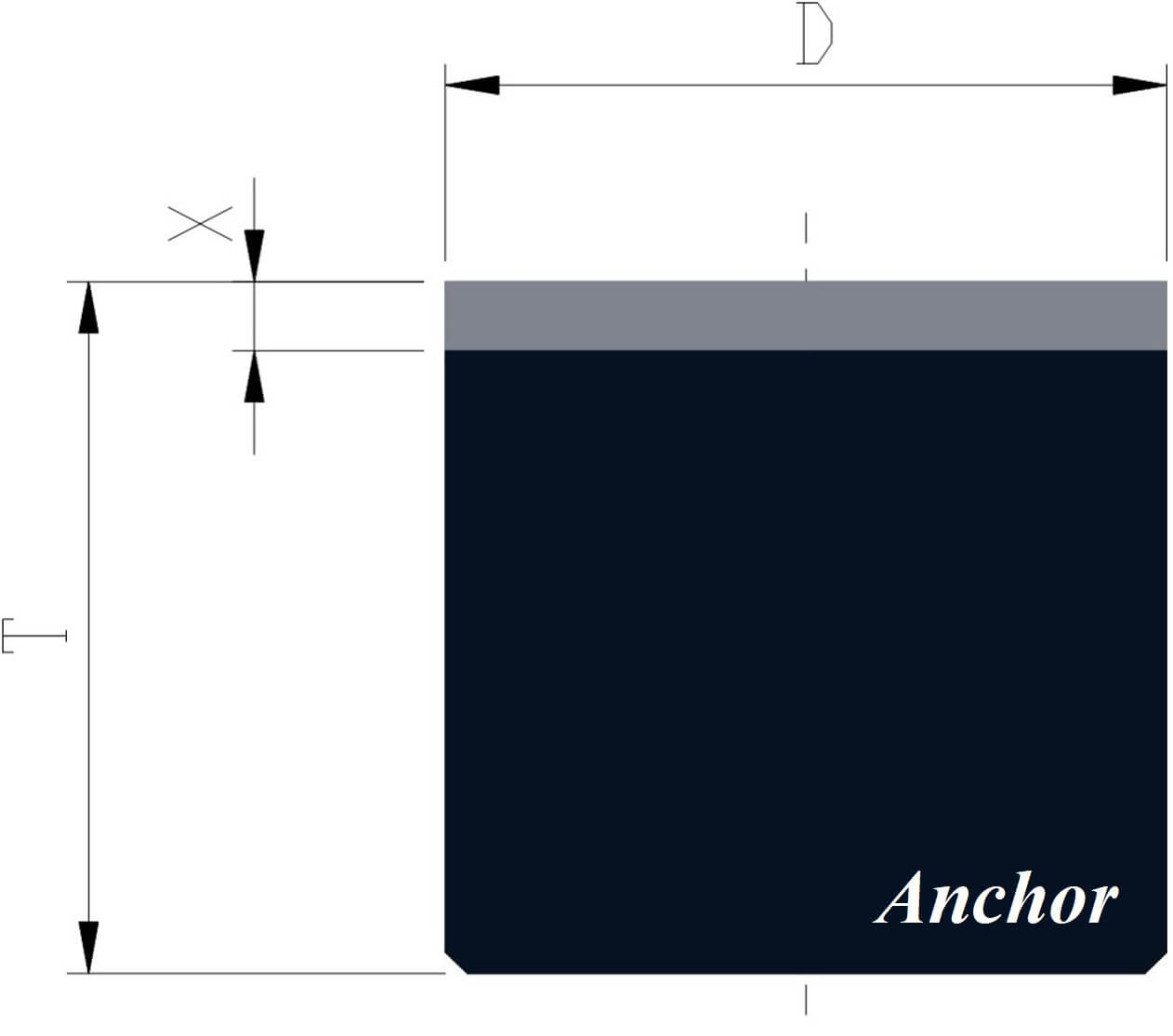

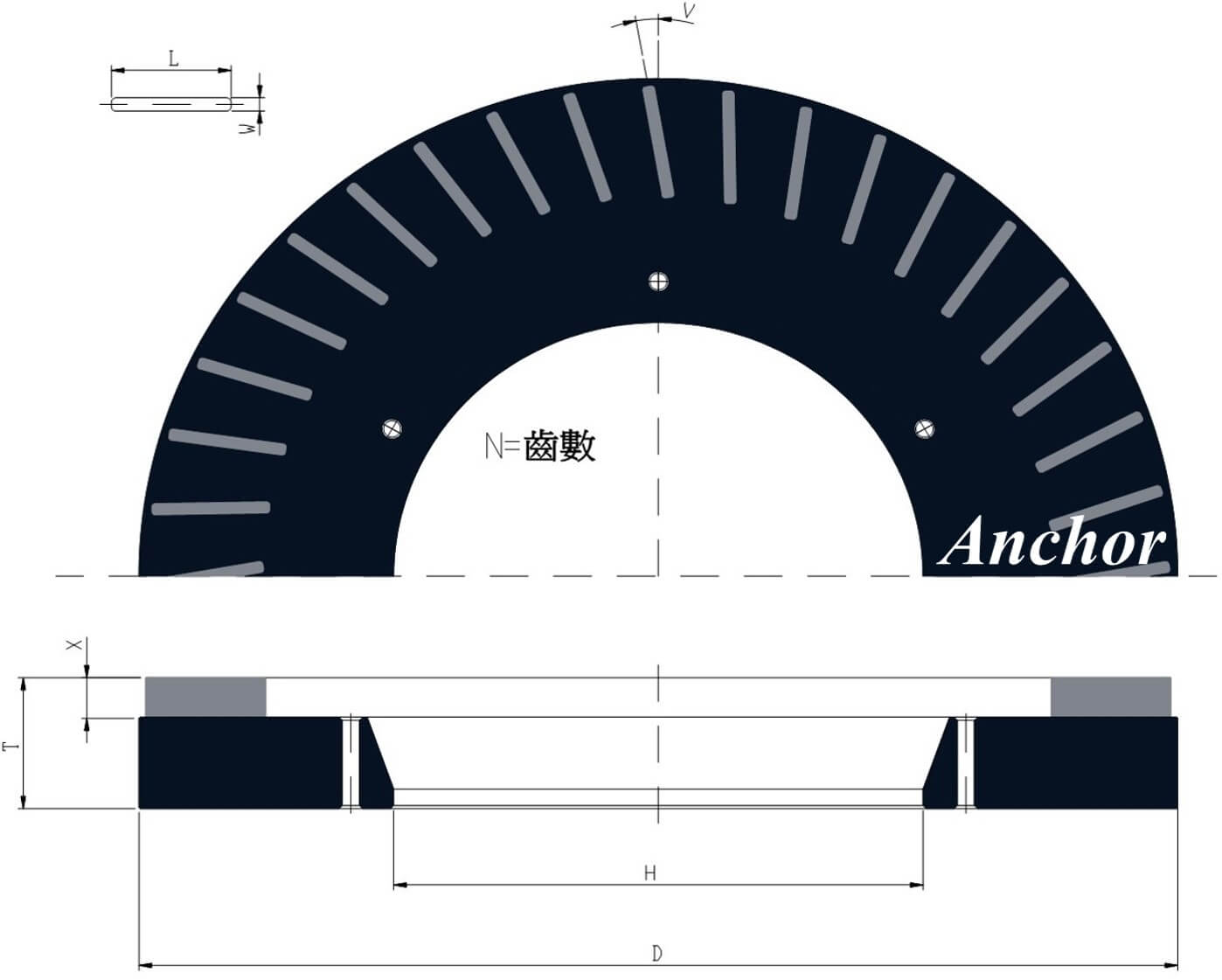

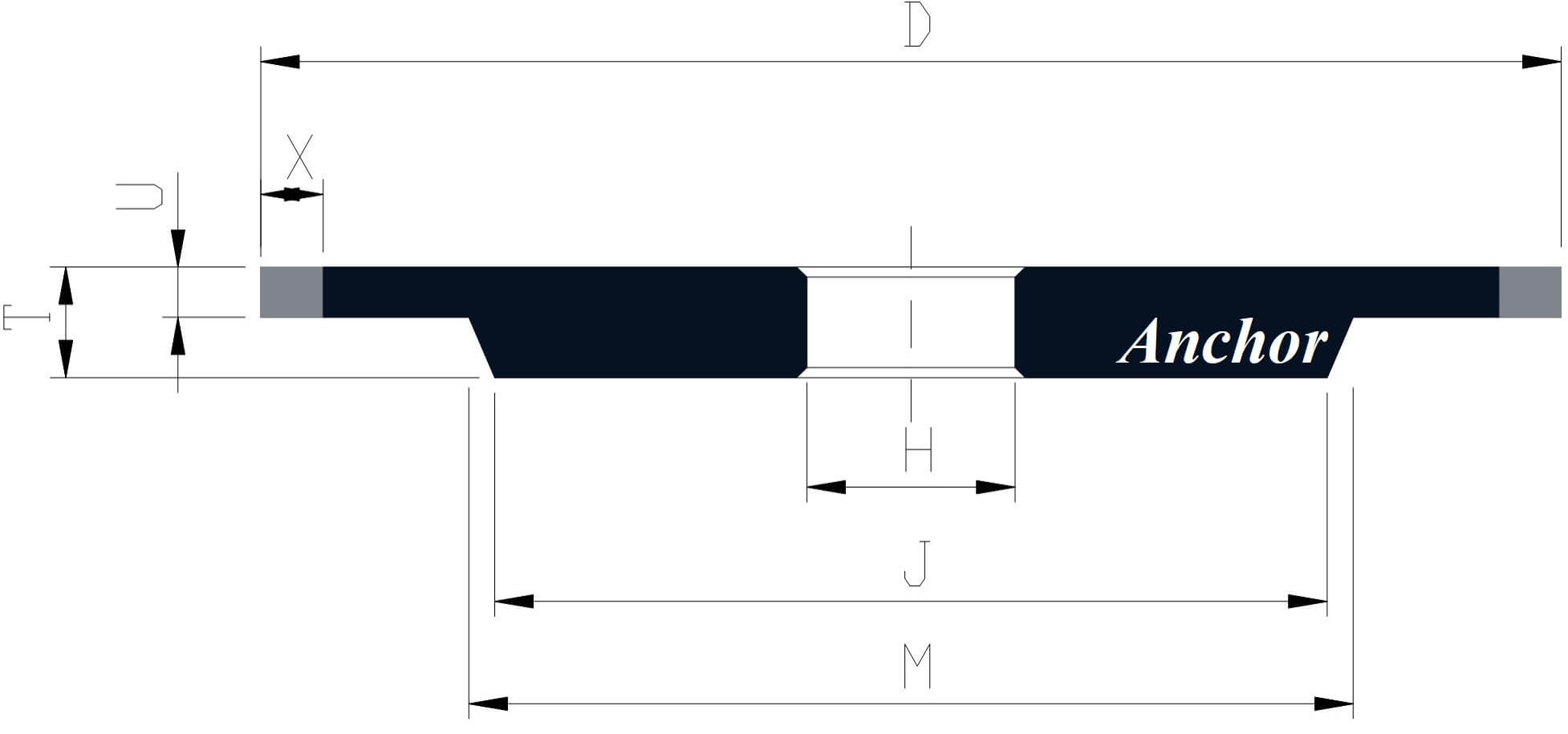

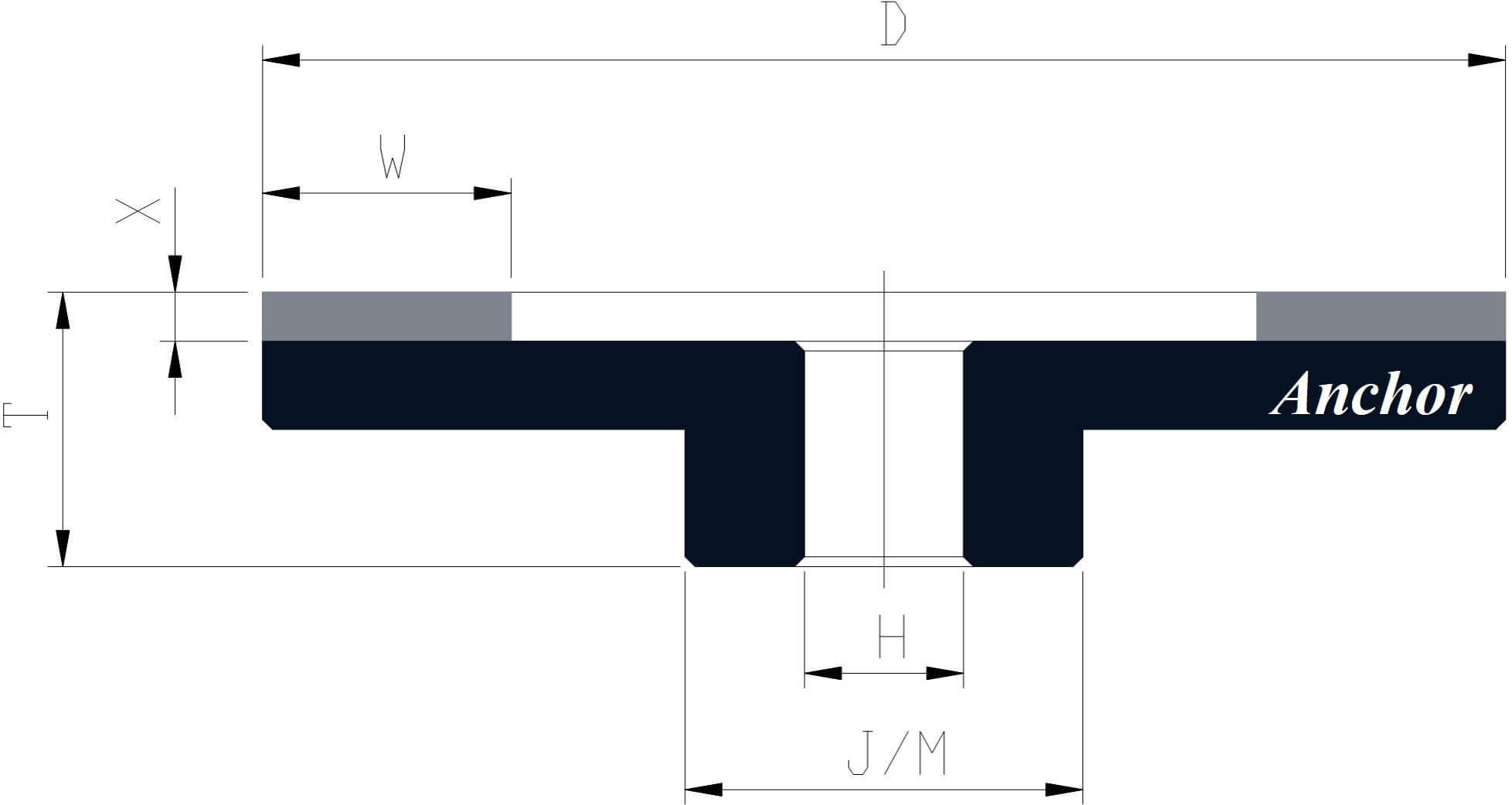

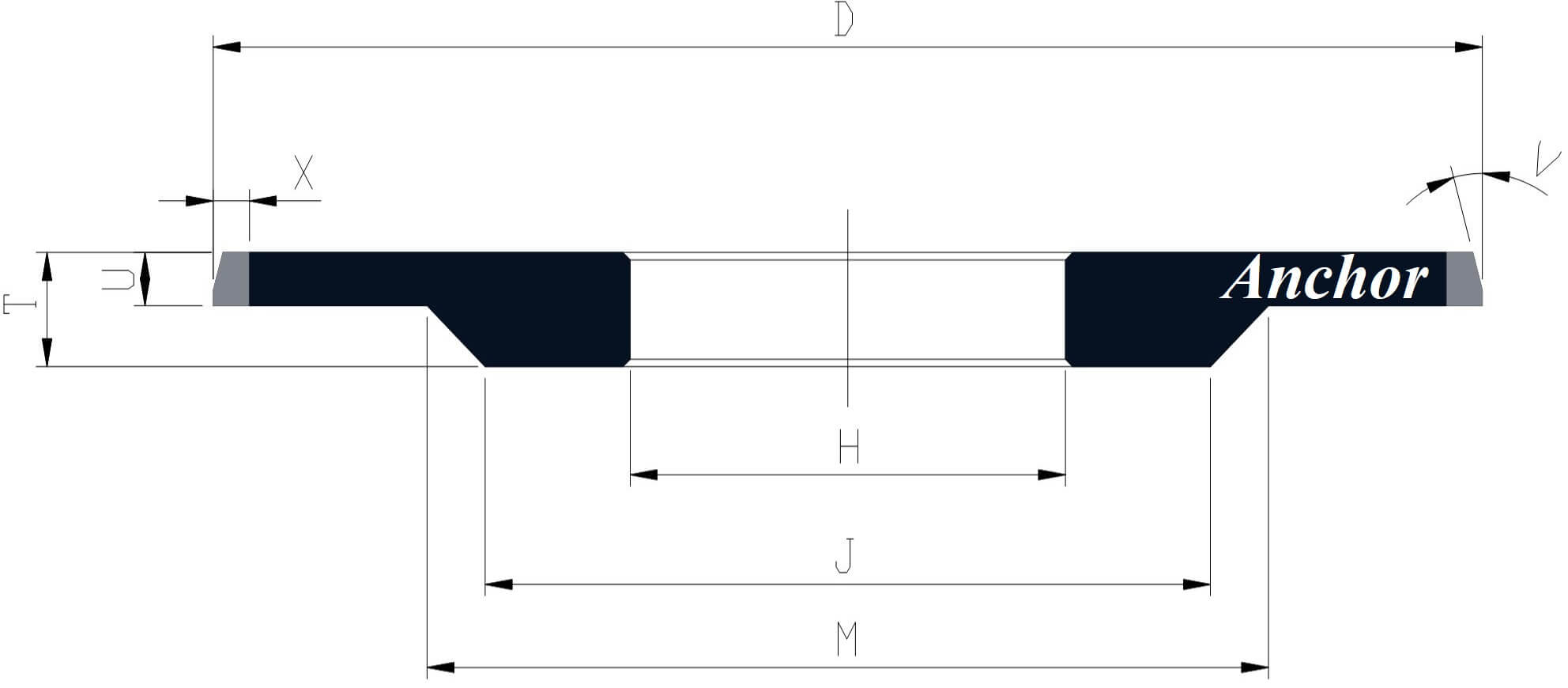

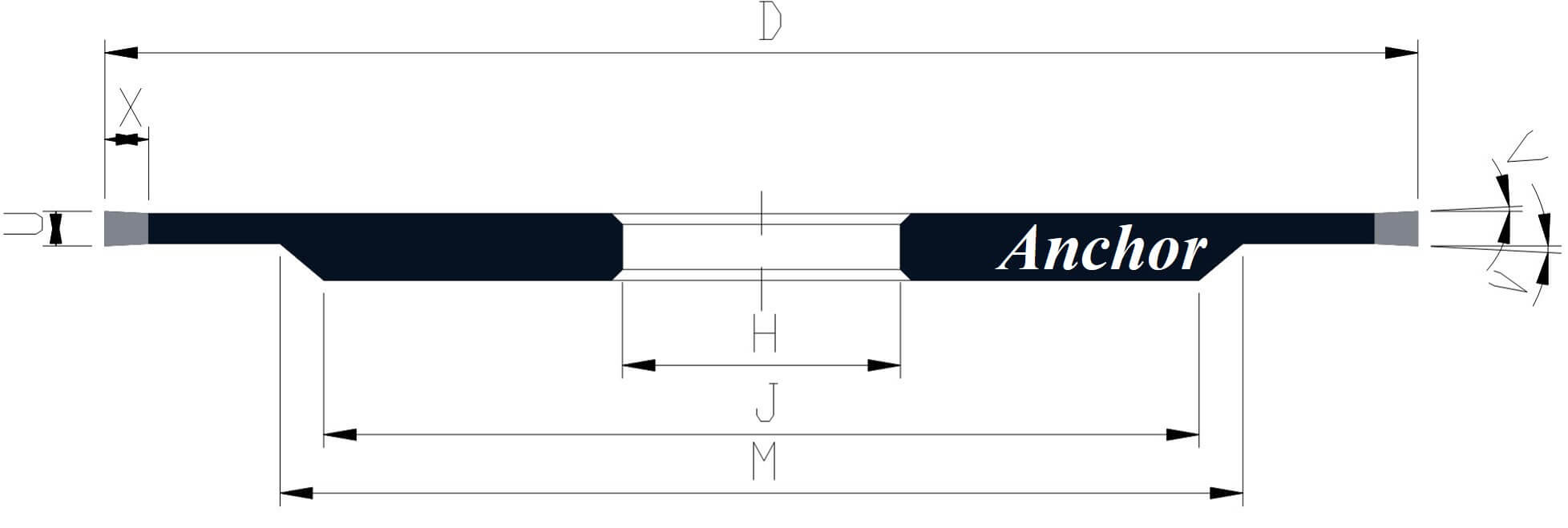

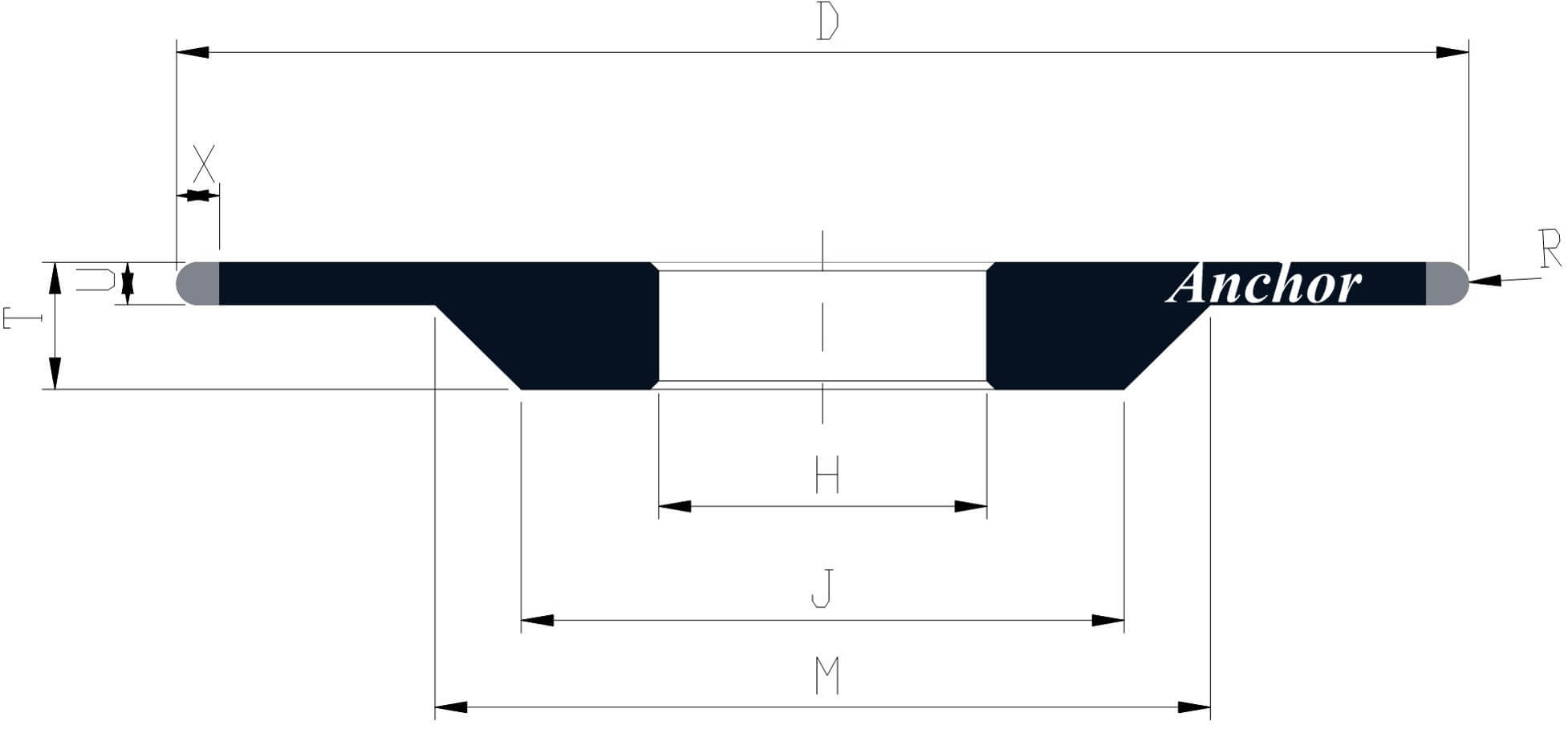

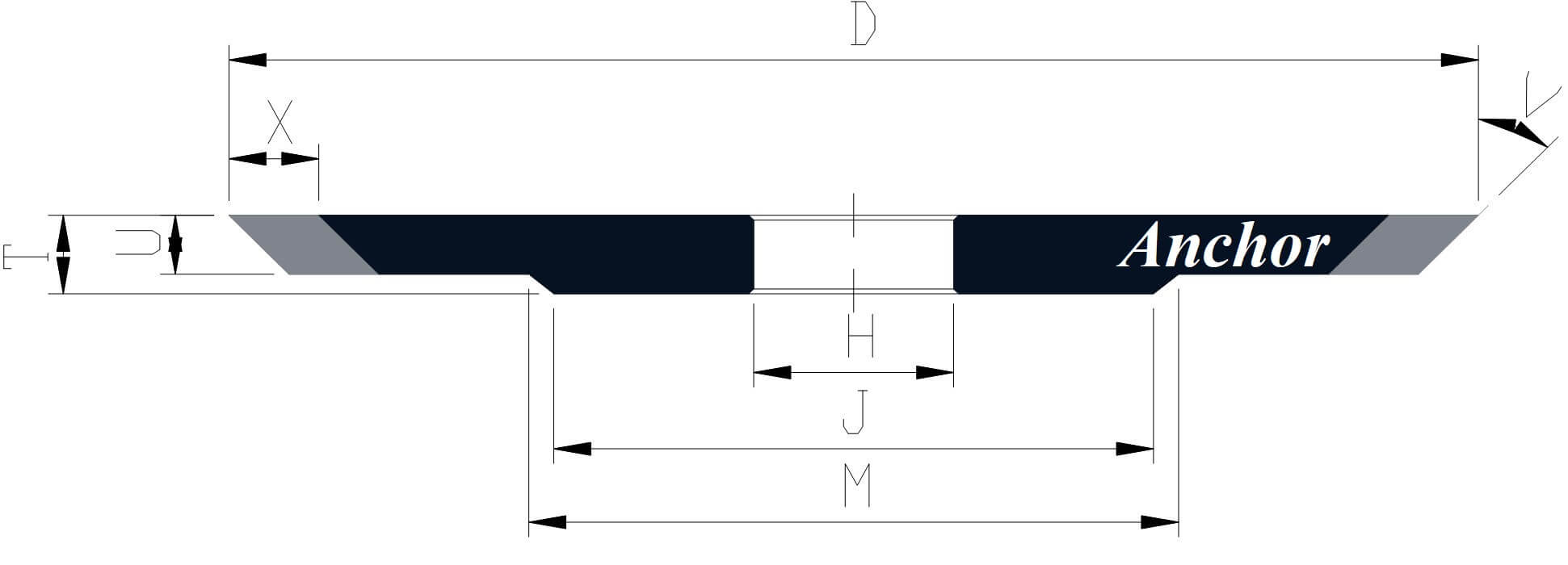

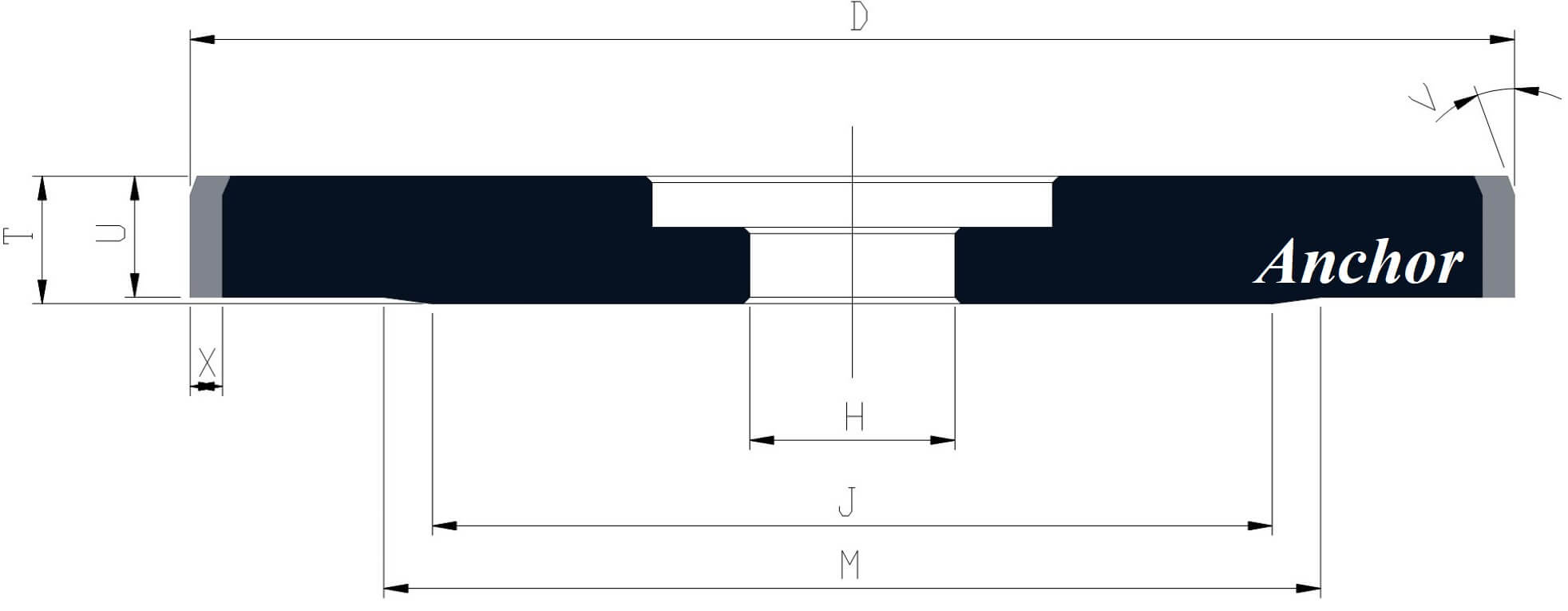

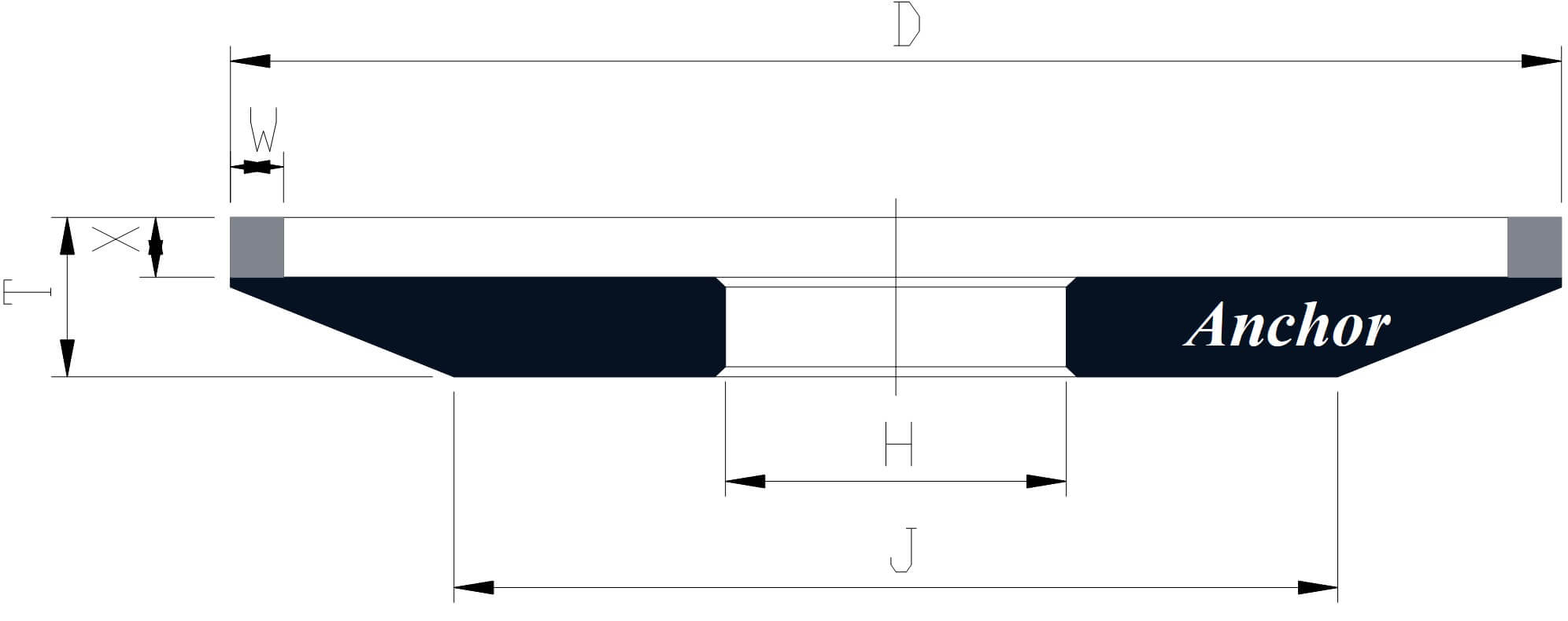

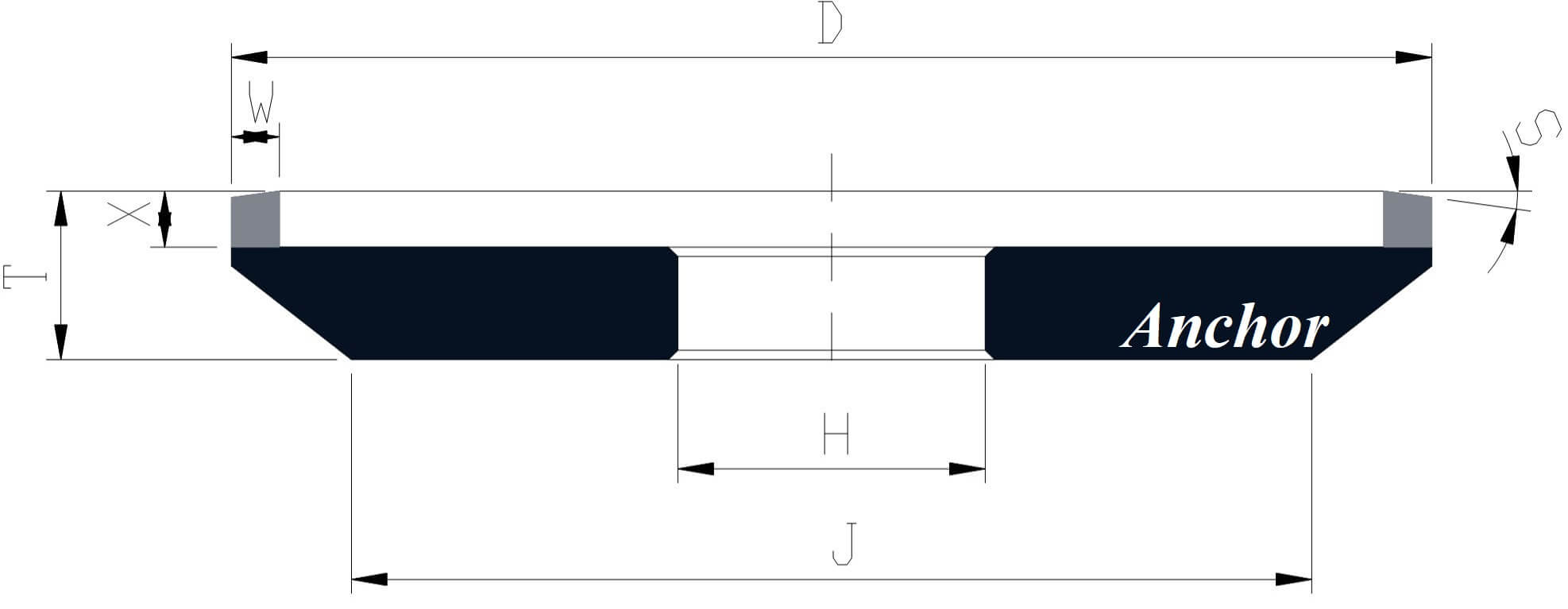

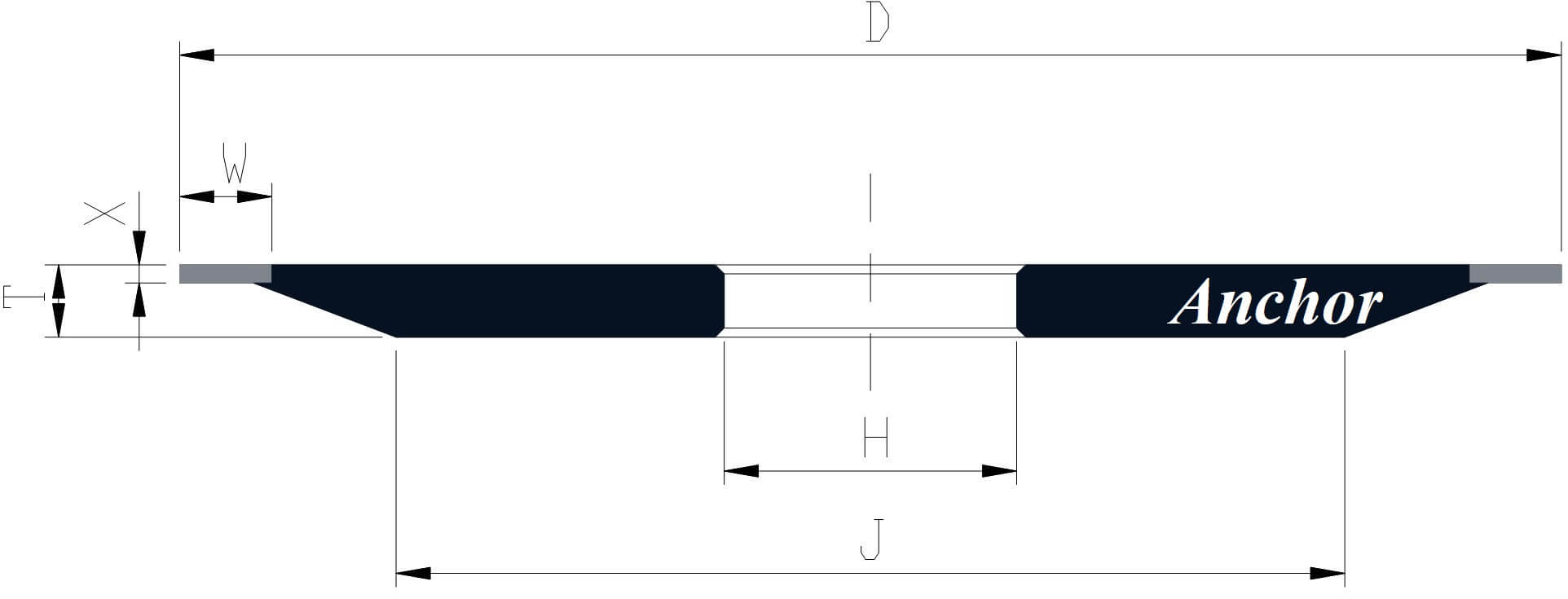

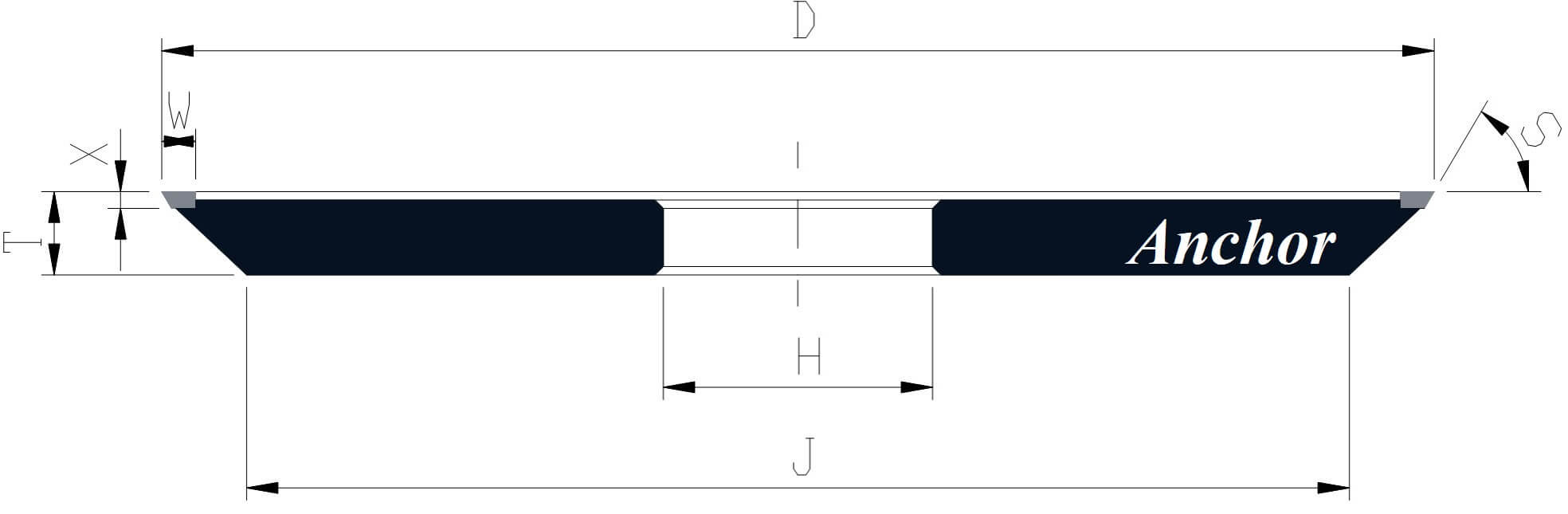

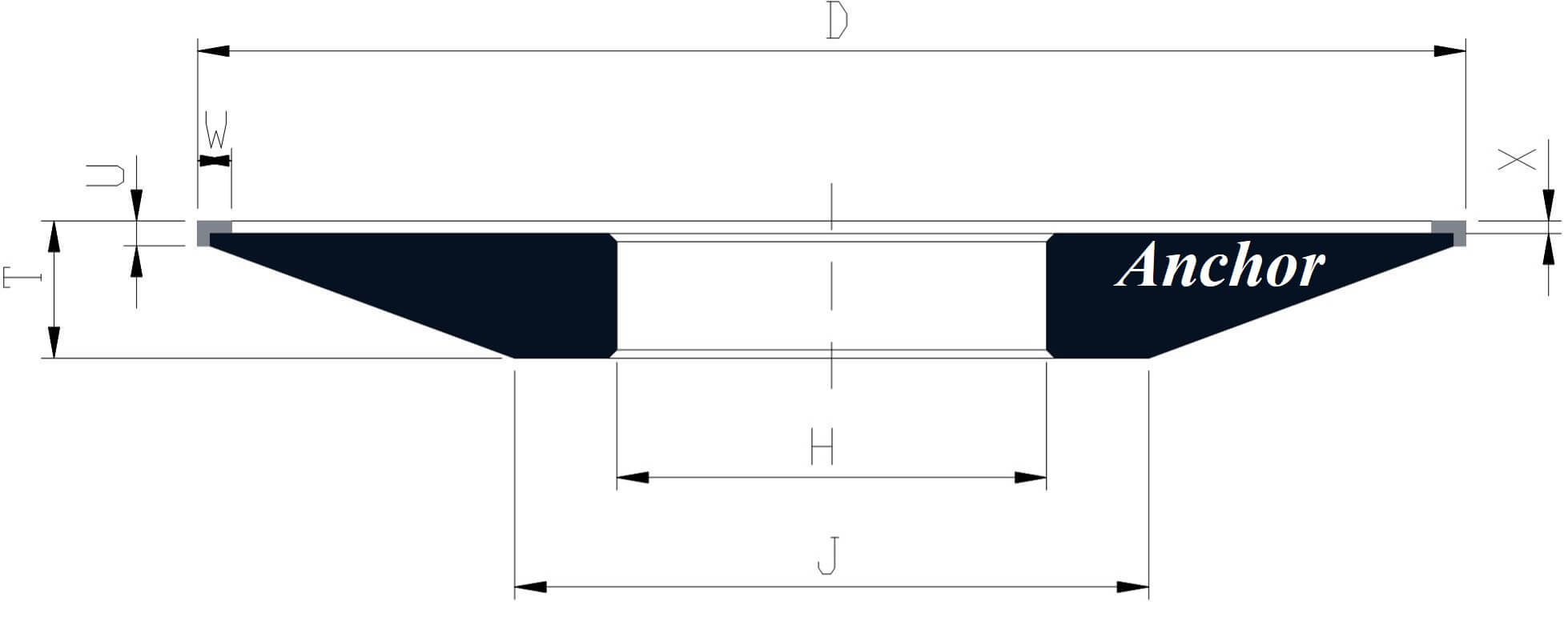

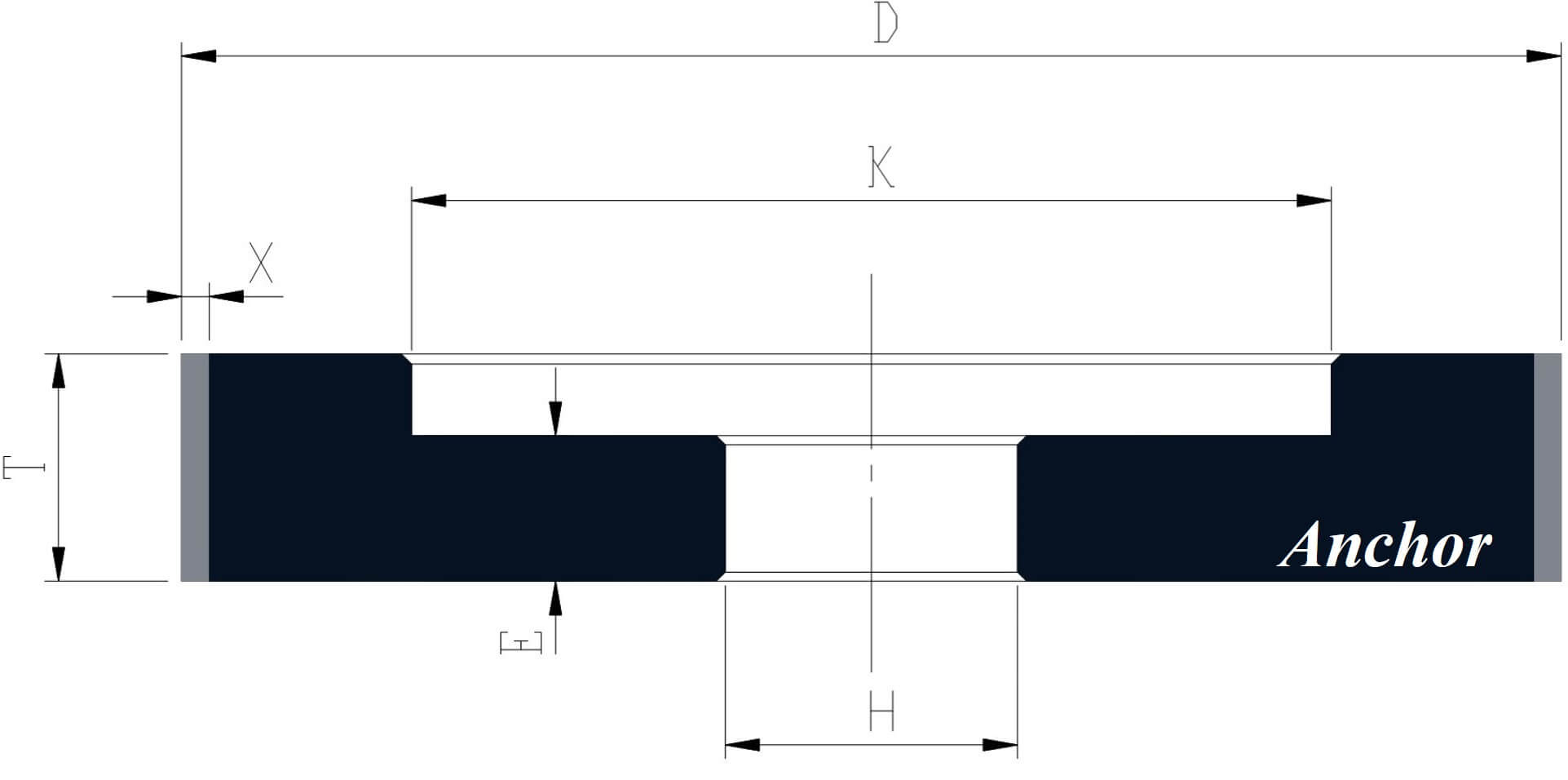

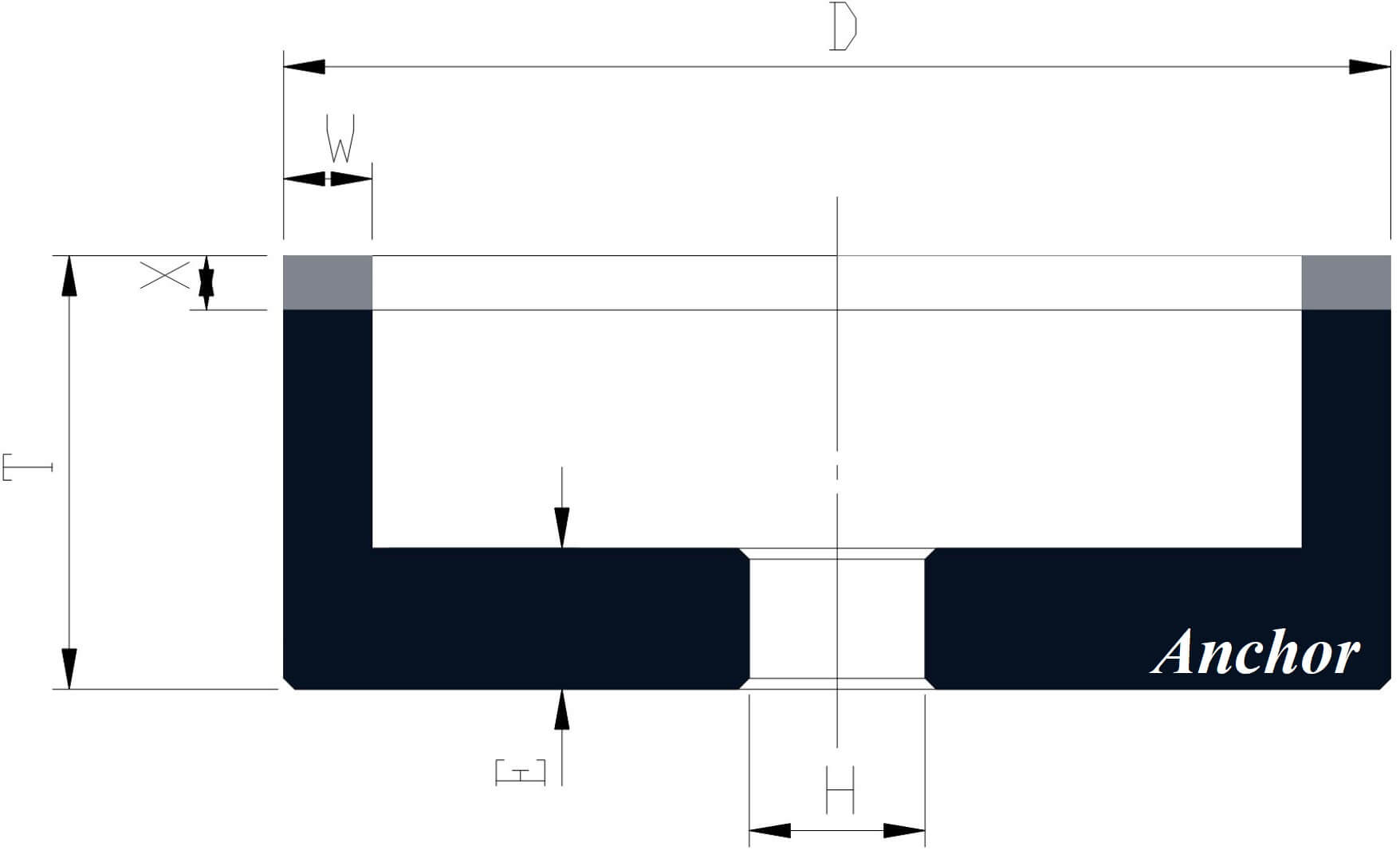

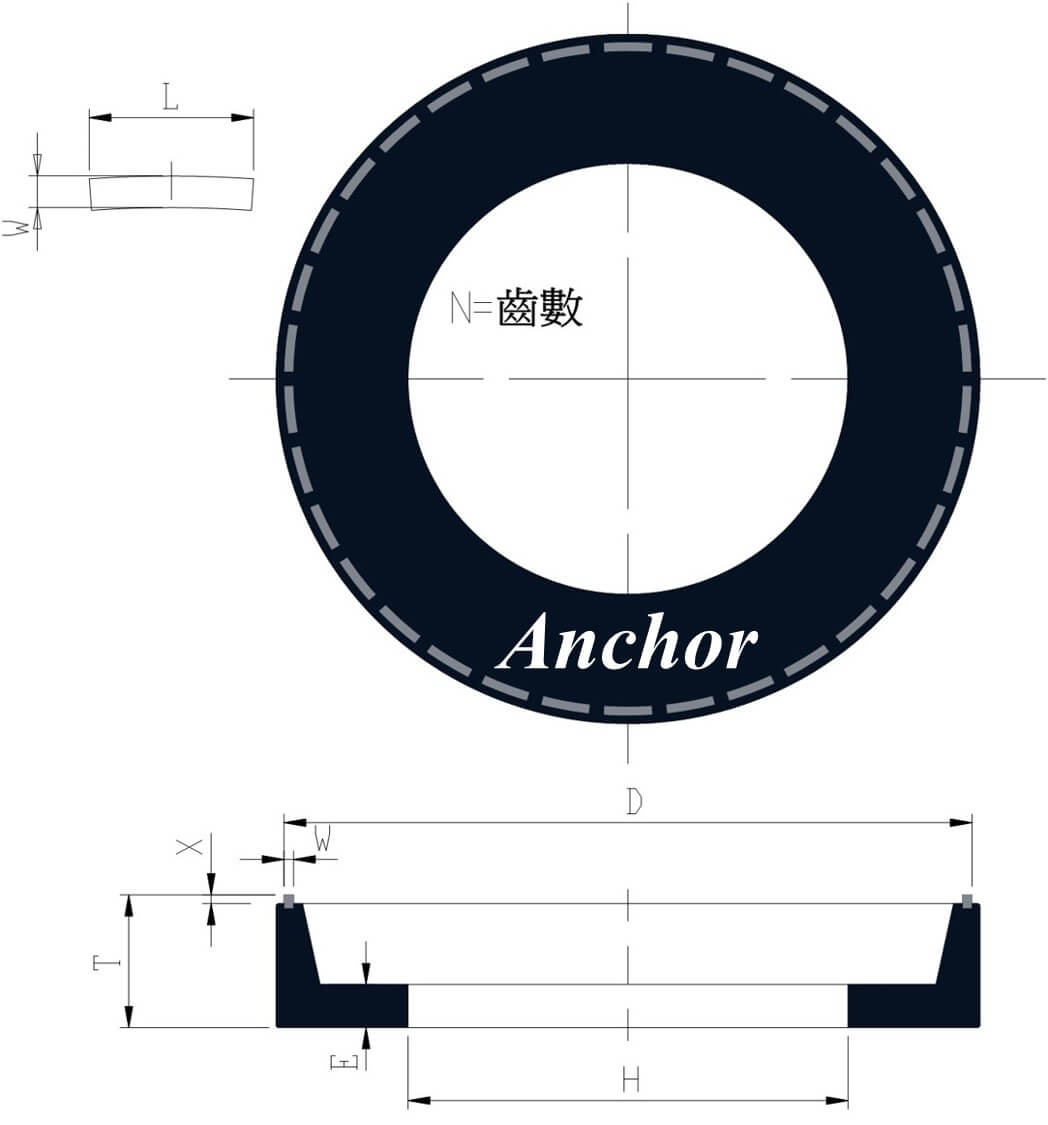

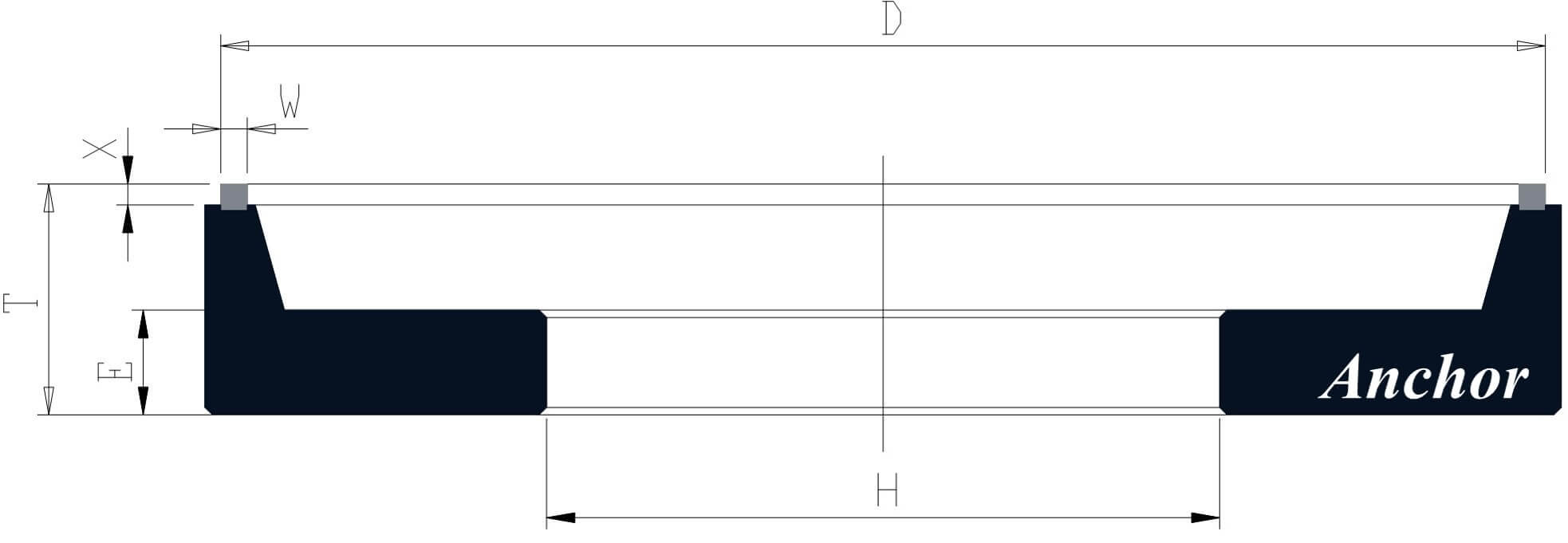

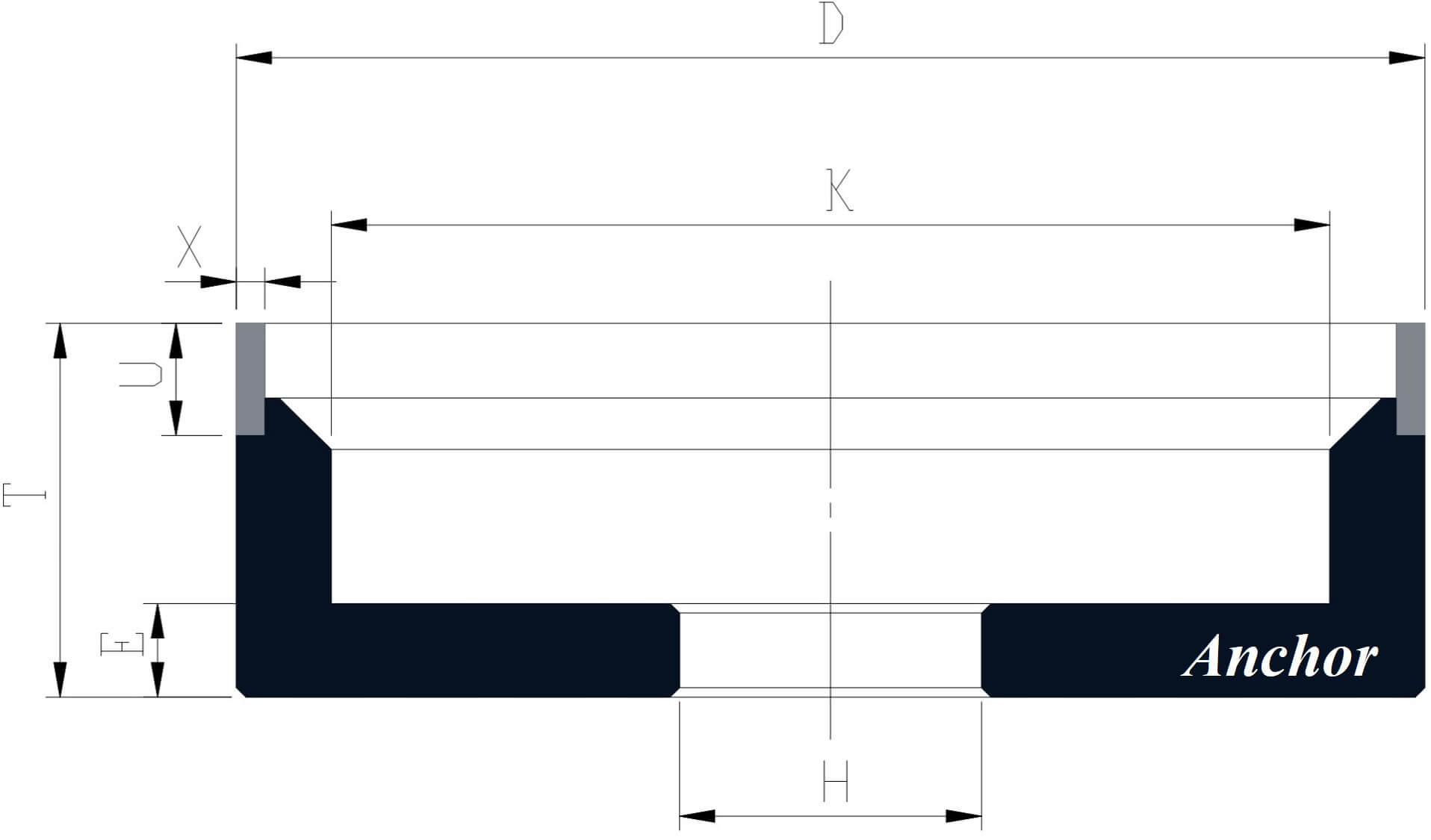

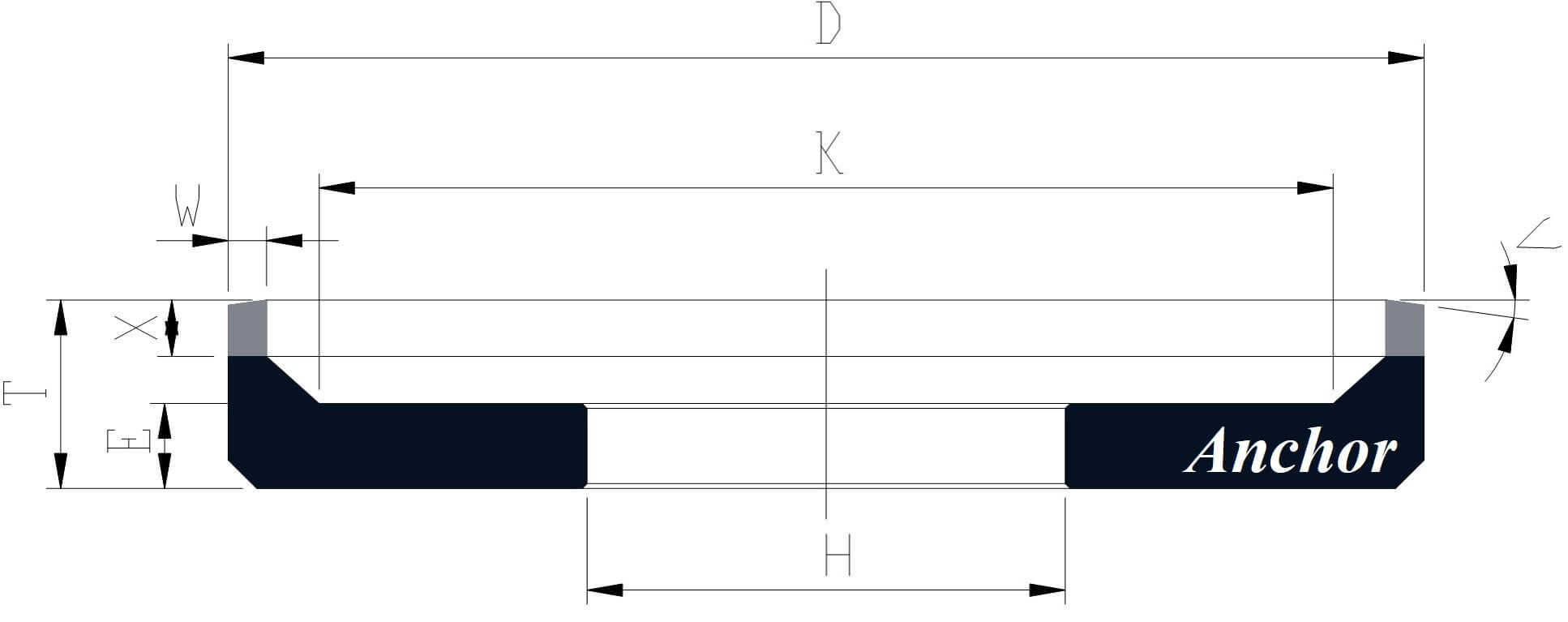

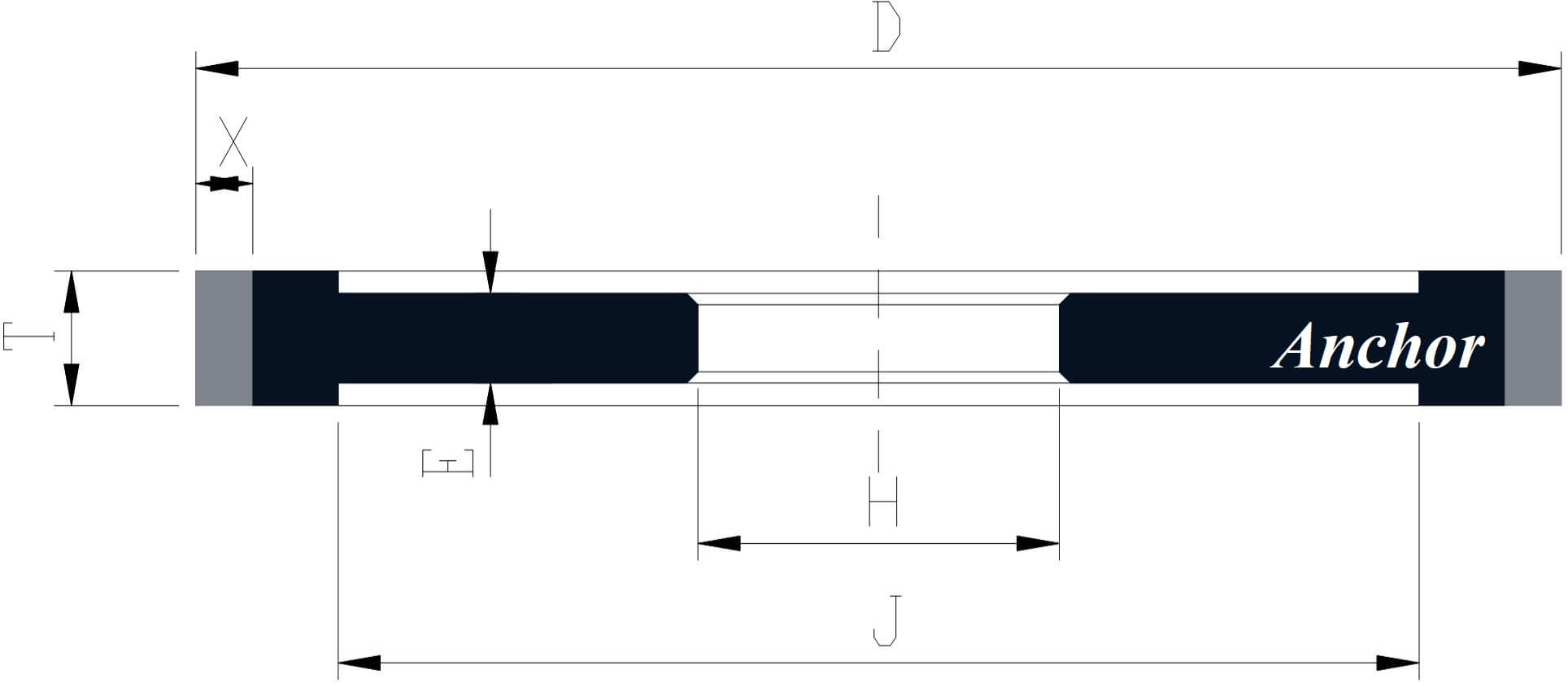

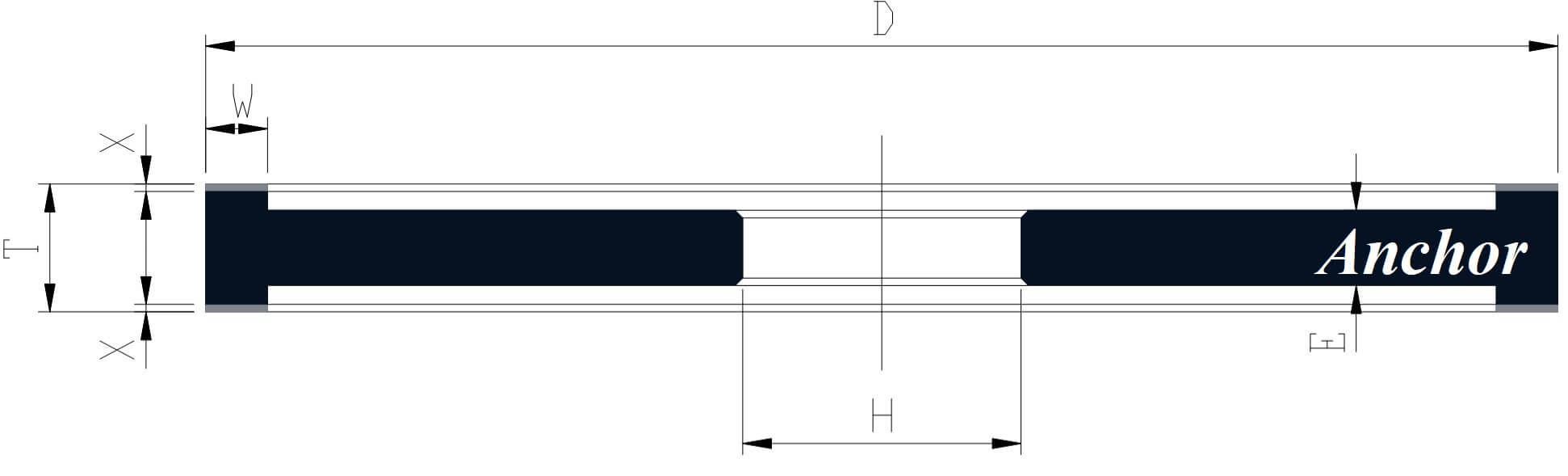

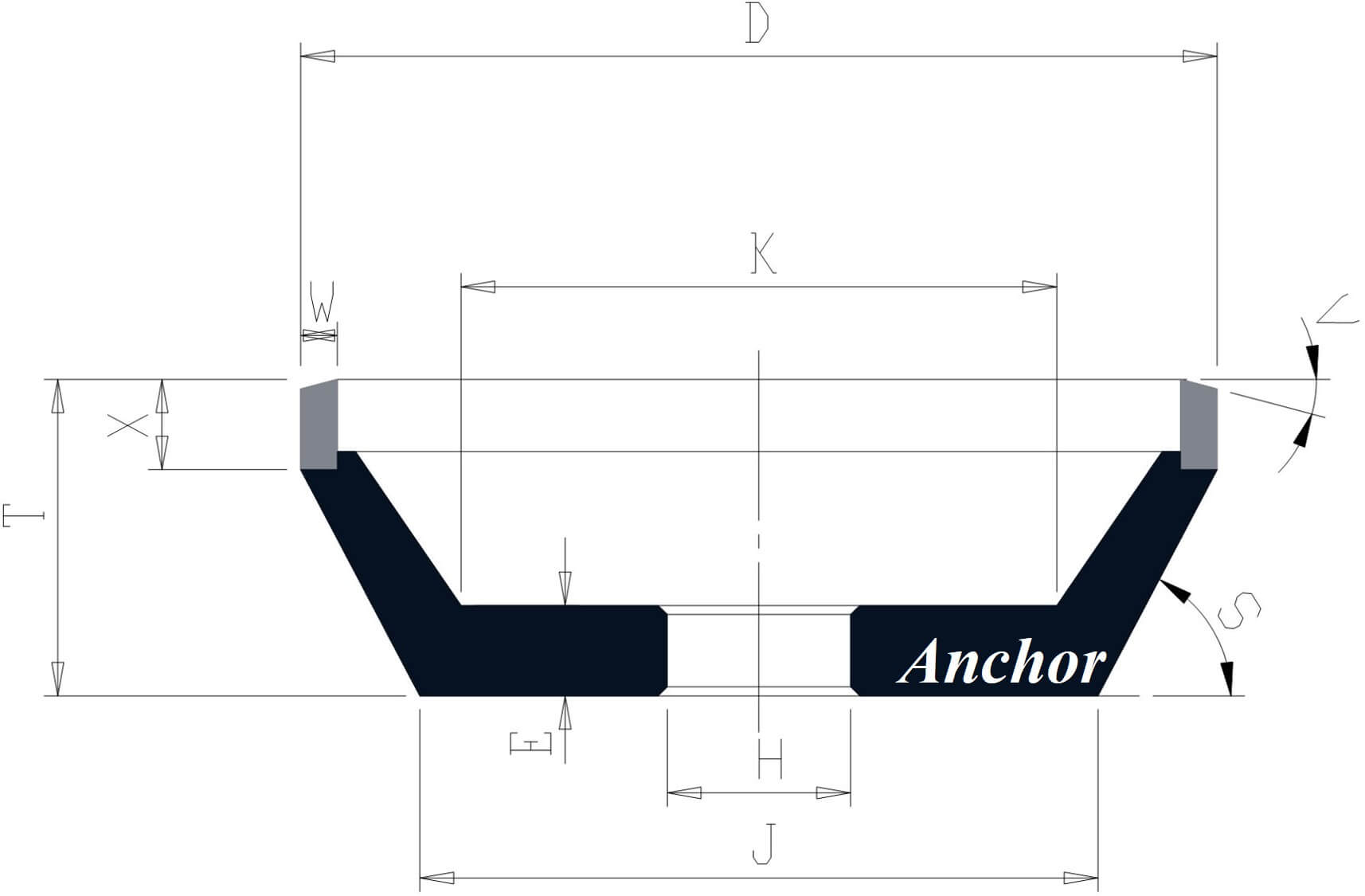

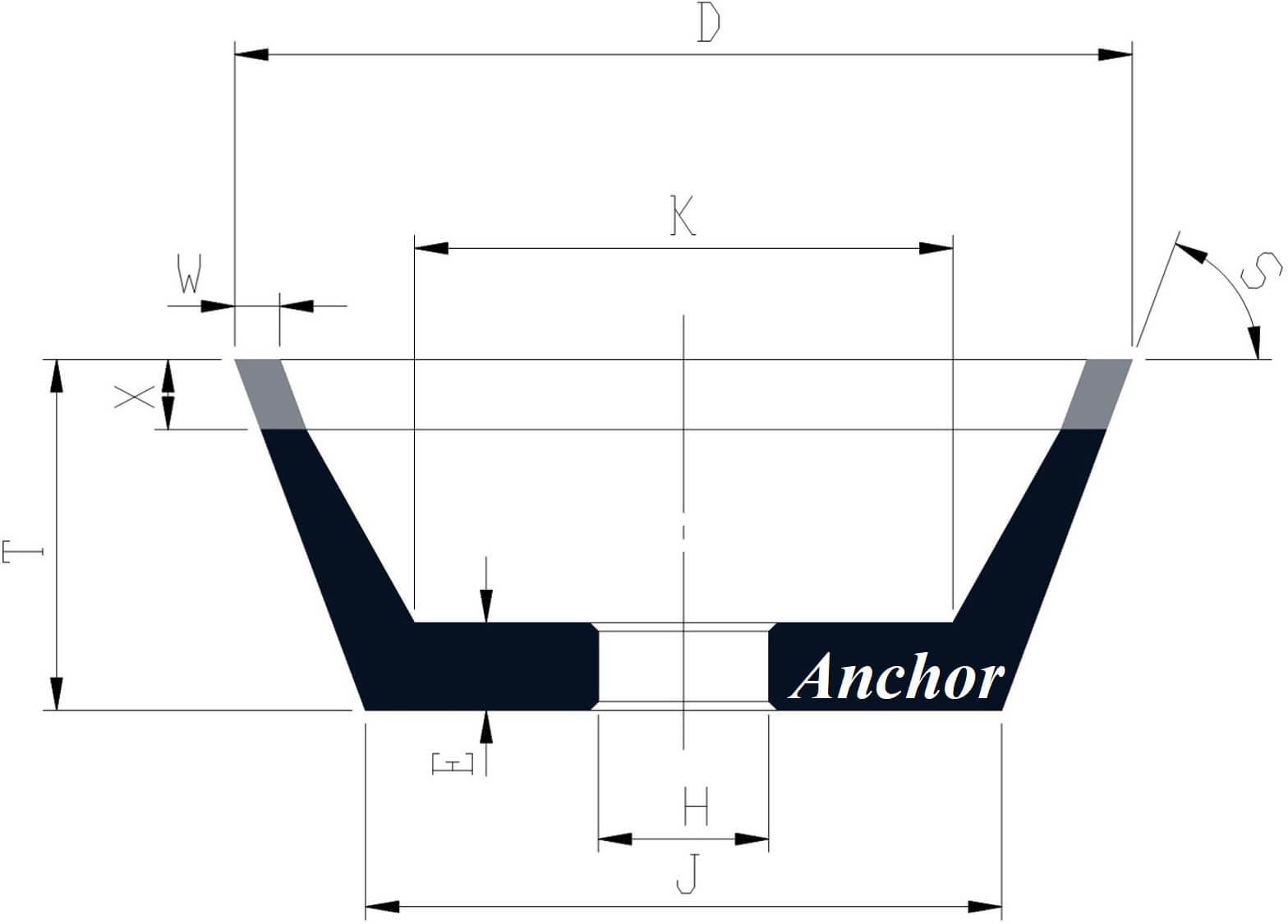

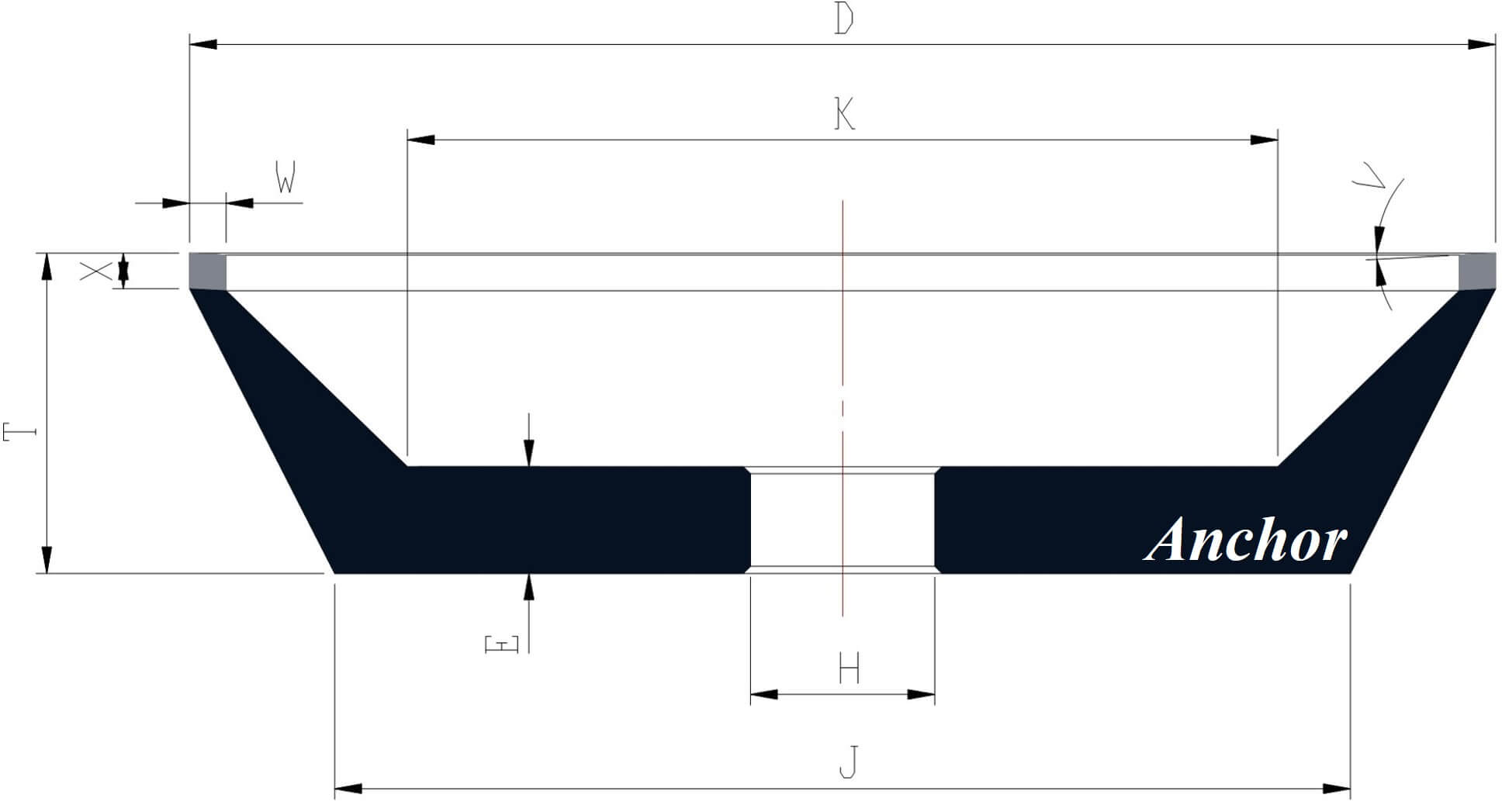

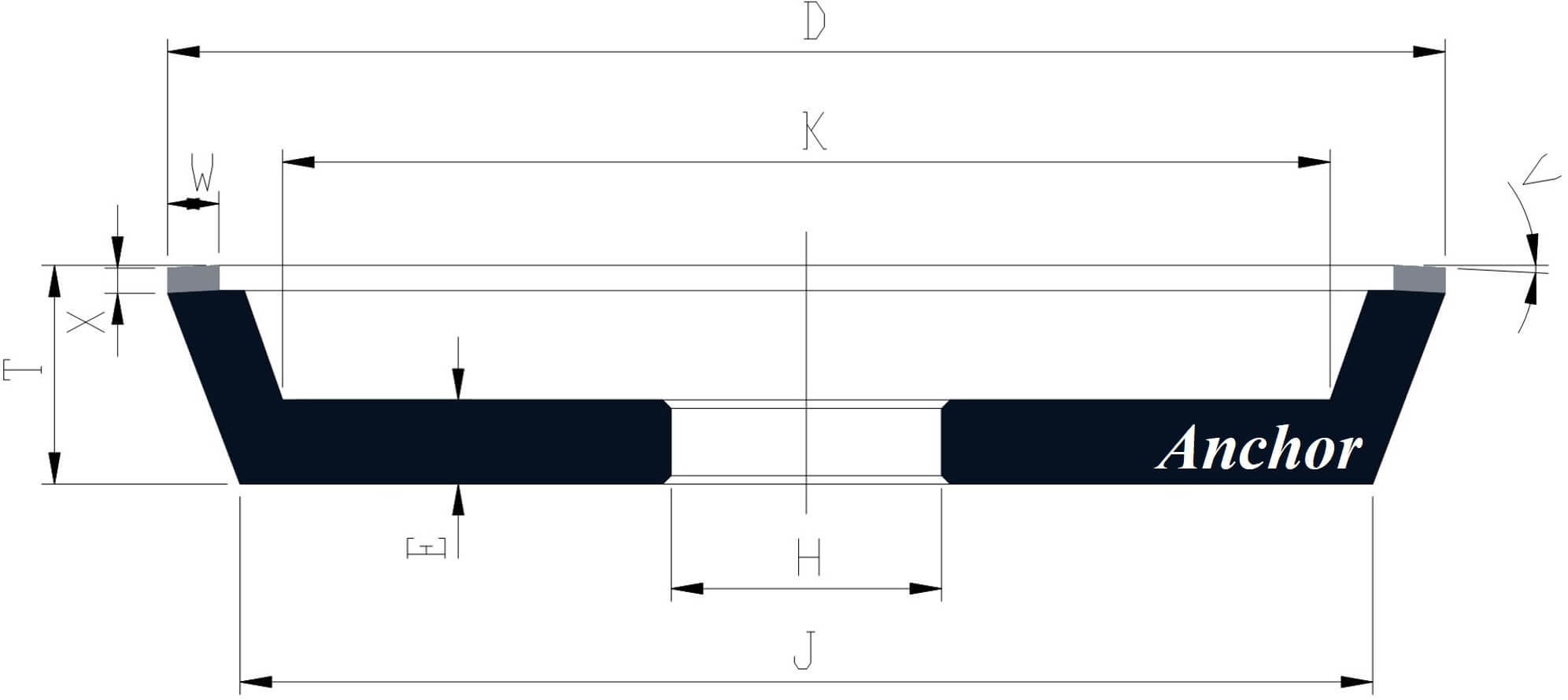

(A)Size Label for Diamond Wheel

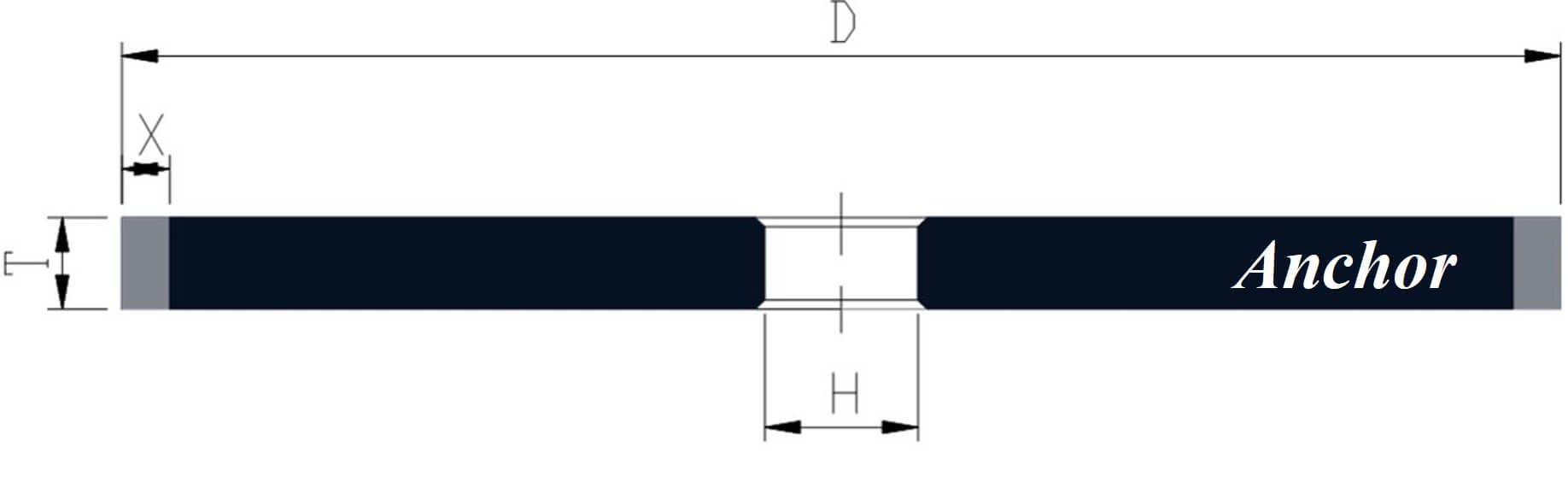

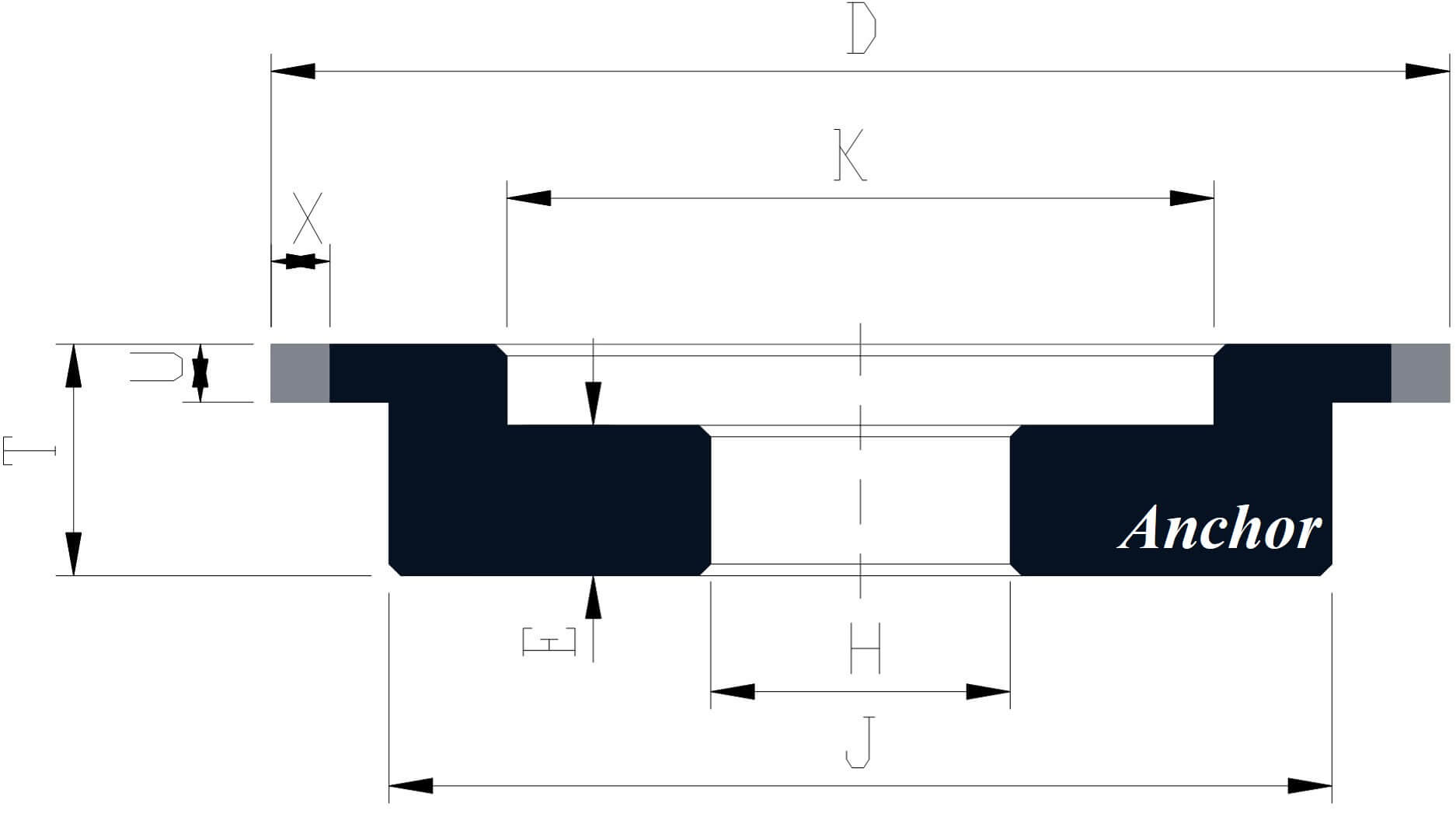

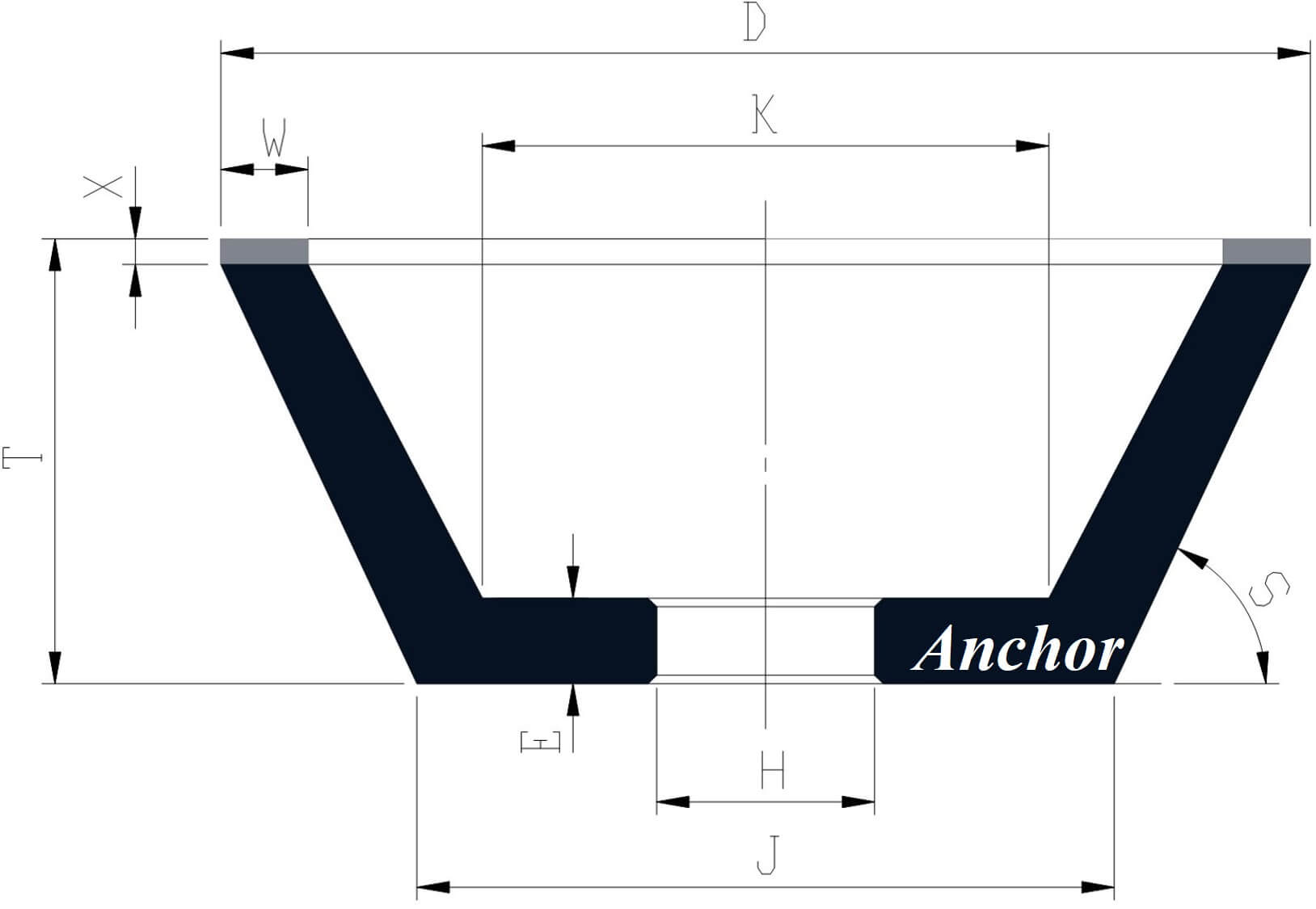

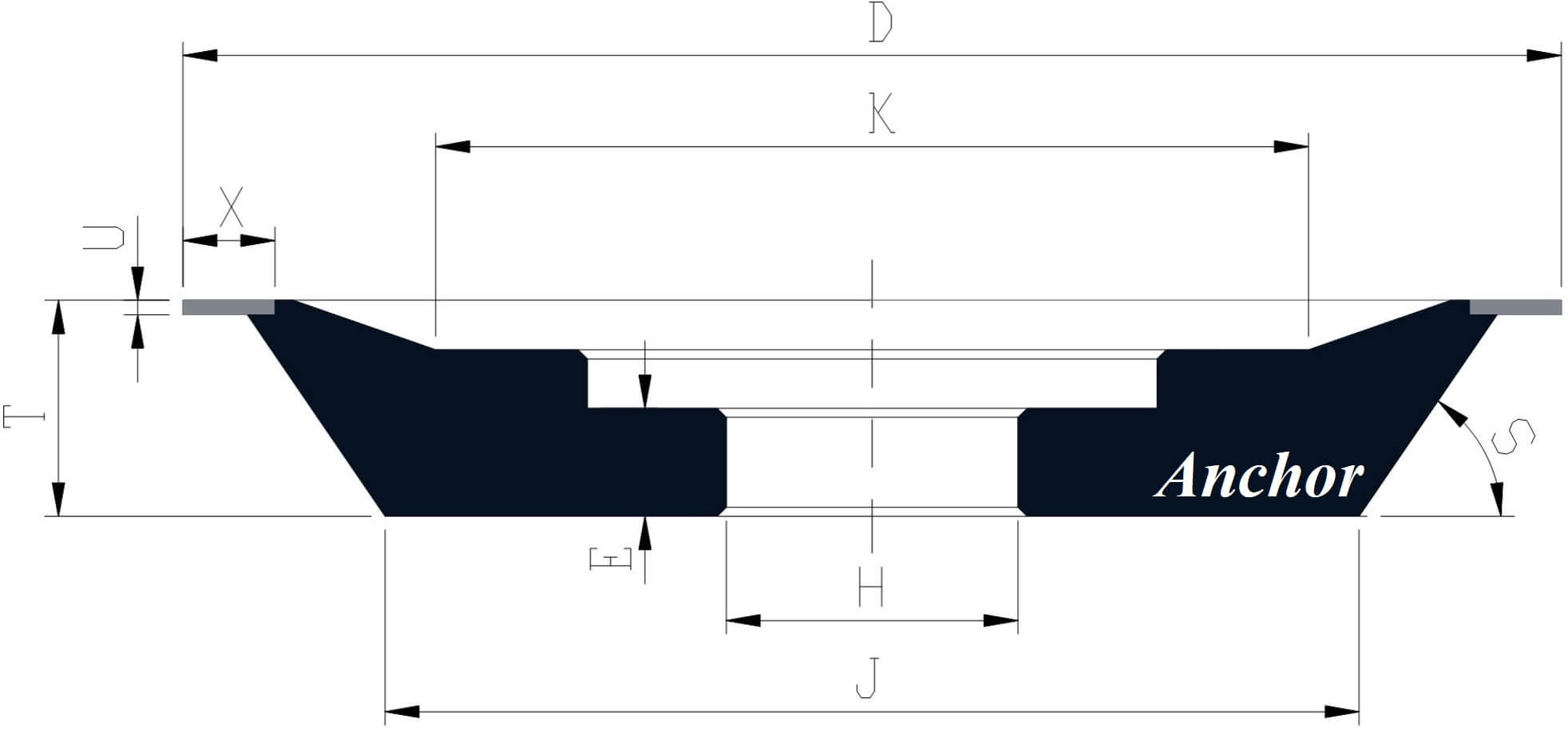

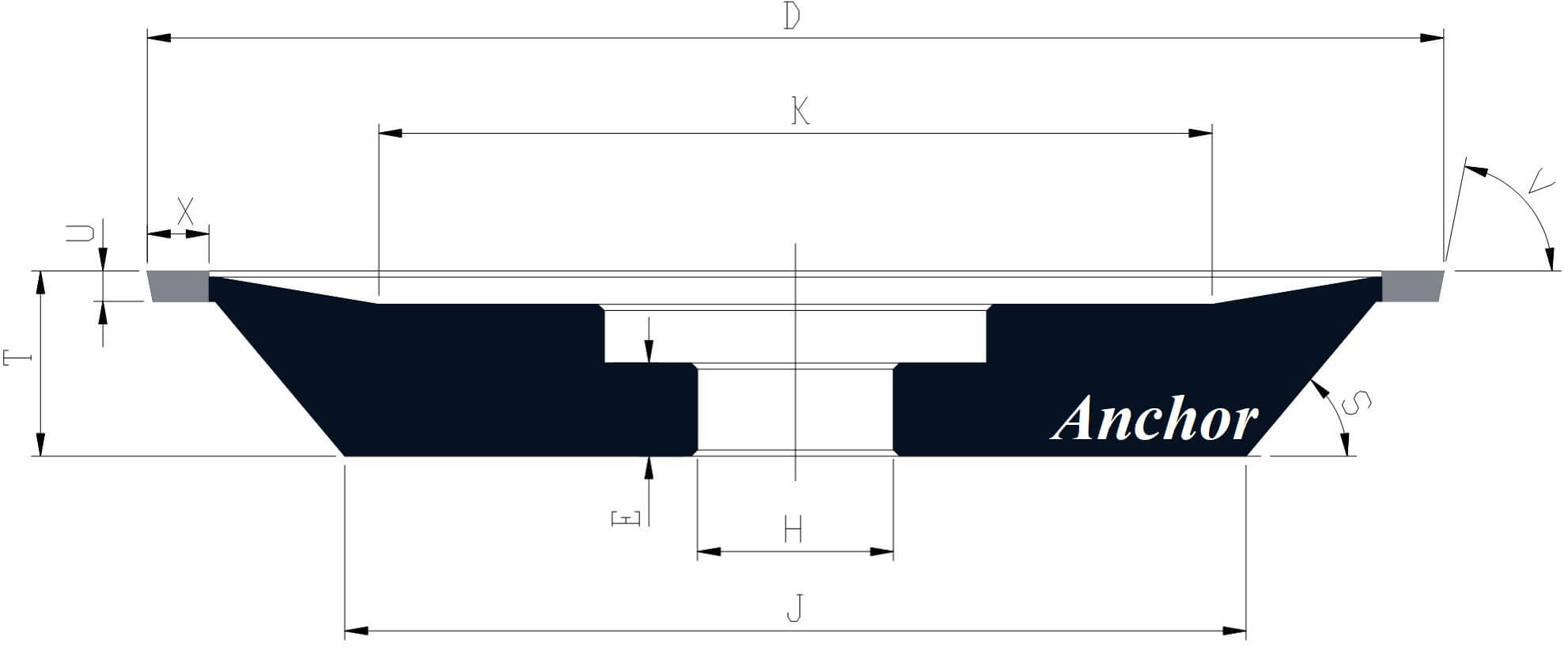

D Diameter

E The Thickness of A Hole Diameter

H Hole Diameter

J The Lowest Surface Diameter of A Wheel

K A Surface Outer Diameter of Internal Side

L Shank Length of Mounted Points

N The Depth of Surplus Indentation

Q Variables, Refer to The Diagram

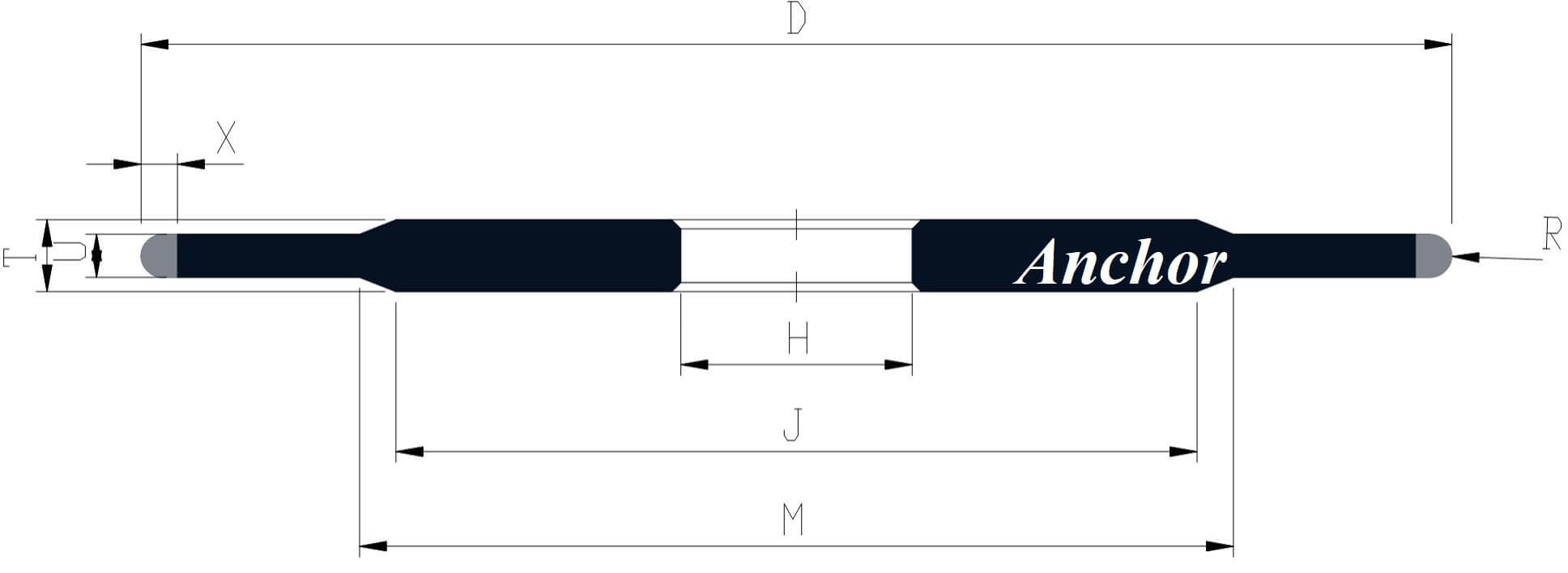

R Radius

S The Angle of Outer Side or The Length of Cylinder

T Total Thickness

U Edge Width

V Angle

W The Thickness and Width of Grinding Surface

X The Thickness of Diamond Layer

Y A Mount Diameter of Mounted wheel

BC Thread Pitch Circle

(B)Specification Marking for Diamond Wheel

(C)Shapes Marking for Diamond Wheel

X

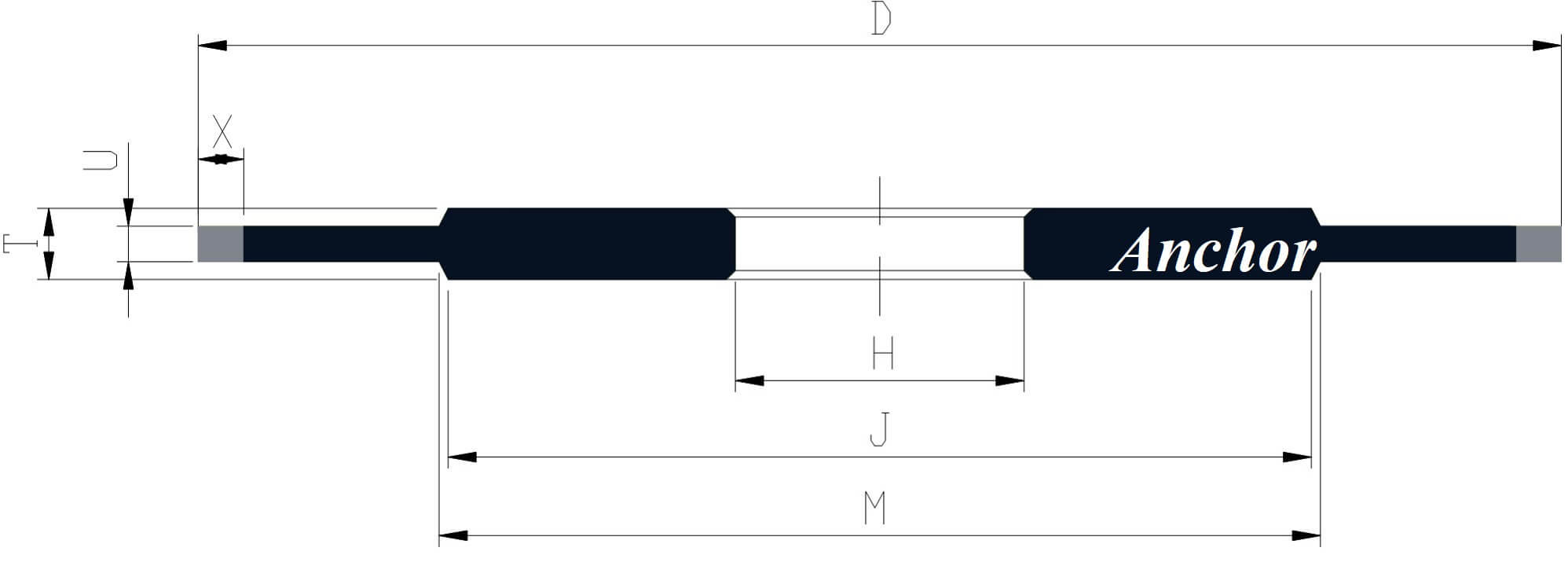

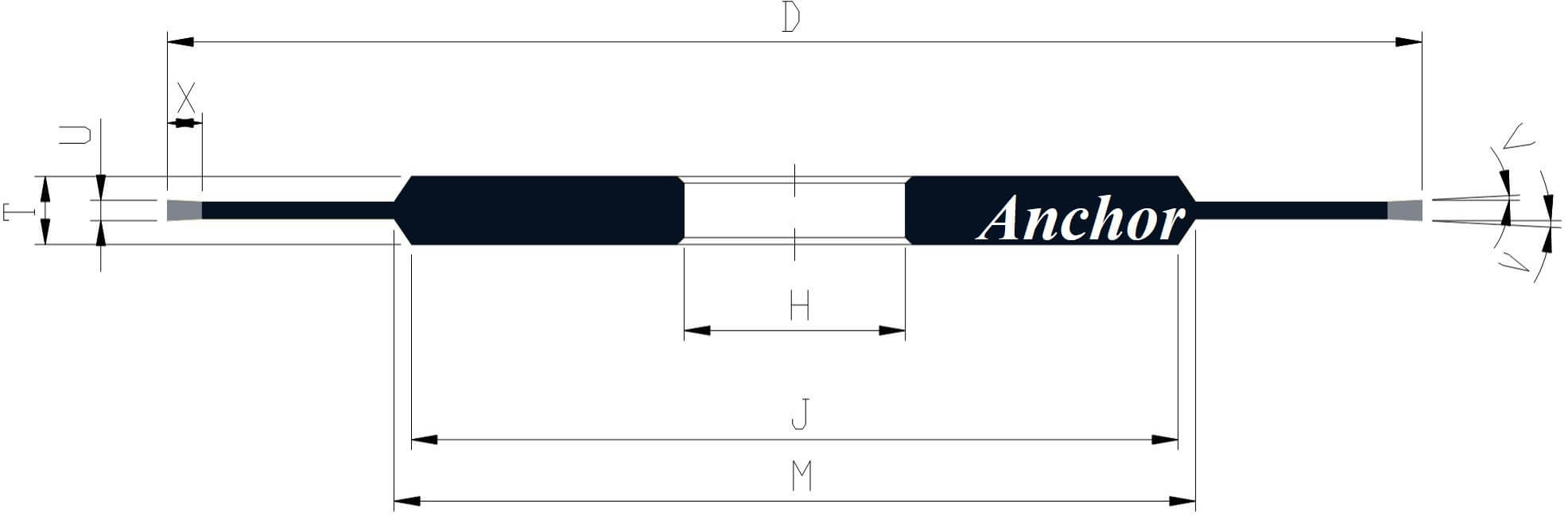

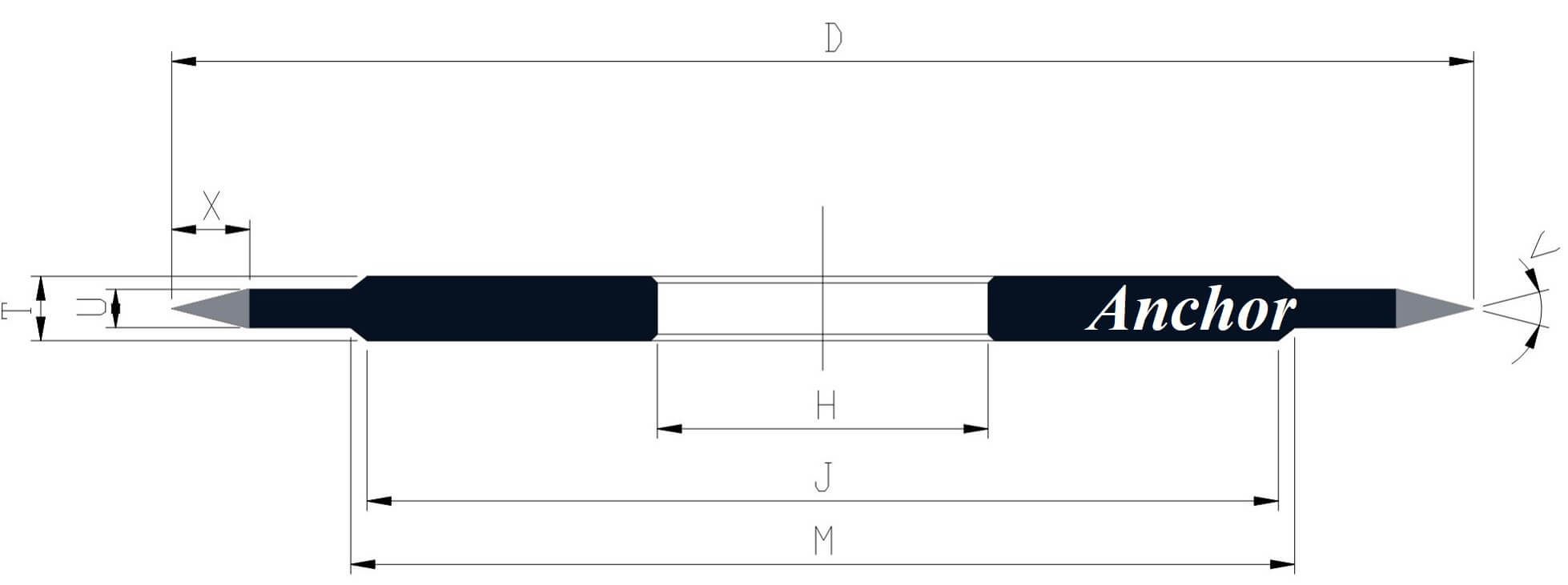

TYPE 1A1 : DxTxHxX

TYPE 1A1R : DxTxHxExX

TYPE 1A6Q : DxTxHxUxX

TYPE 1A8 : DxTxH

TYPE 1E1 : DxTxHxXxV

TYPE 1B1 : DxTxHxXxV

TYPE 1E9 : DxTxHxUxXxV

TYPE 1EE1 : DxTxHxXxV

TYPE 1F1 : DxTxHxXxR

TYPE 1FF1 : DxTxHxXxR

TYPE 1V1 : DxTxHxXxV

TYPE 1V1P : DxTxHxExXxV

TYPE 1A1RSS : DxTxHxLxXxNxB

TYPE 2A2 : DxTxHxExXxW

TYPE 2V5 : DxTxHxExX

TYPE 2P : DxTxX

TYPE 2A2SX : DxTxHxLxWxXxNxV

TYPE 3A1 : DxTxHxJxMxUxX

TYPE 3A2 : DxTxHxJxMxWxX

TYPE 3B1 : DxTxHxJxMxUxXxS

TYPE 3D1 : DxTxHxJxMxUxXxV

TYPE 3F1 : DxTxHxJxMxUxRxX

TYPE 3V1 : DxTxHxJxMxUxXxV

TYPE 3Y1 : DxTxHxJxMxUxXxV

TYPE 4A2 : DxTxHxJxWxX

TYPE 4B2 : DxTxHxJxWxX

TYPE 4A9 : DxTxHxJxWxX

TYPE 4B9 : DxTxHxJxWxXxS

TYPE 4C9 : DxTxHxJxWxUxX

TYPE 6A1 : DxTxHxExKxX

TYPE 6A2 : DxTxHxExWxX

TYPE 6A2S : DxTxHxExLxWxXxN

TYPE 6A7 : DxTxHxExWxX

TYPE 6A9 : DxTxHxExKxUxX

TYPE 6B2 : DxTxHxExKxWxXxV

TYPE 9A1 : DxTxHxExJxX

TYPE 9A3 : DxTxHxExWxX

TYPE 11A1 : DxTxHxExKxJxUxX

TYPE 11A2 : DxTxHxExKxJxWxX

TYPE 11A9 : DxTxHxExKxJxUxX

TYPE 11B1 : DxTxHxExKxJxUxXxV

TYPE 11B9 : DxTxHxExKxJxWxXxV

TYPE 11V2 : DxTxHxExKxJxWxXxS

TYPE 11V4 : DxTxHxExKxJxWxXxV

TYPE 11V5 : DxTxHxExKxJxWxXxV

TYPE 11V9 : DxTxHxExKxJxUxXxS

TYPE 12A2 : DxTxHxExKxJxWxXxB

TYPE 12C9 : DxTxHxExKxJxWxUxX

TYPE 12V9 : DxTxHxExKxJxUxXxS

TYPE 14A1 : DxTxHxJxMxUxX

TYPE 14D1 : DxTxHxJxMxUxXxV

TYPE 14E1 : DxTxHxJxMxUxXxV

TYPE 14F1 : DxTxHxJxMxUxRxX

TYPE 14V1 : DxTxHxJxMxUxXxV

TYPE DW : DxTxYxLxX

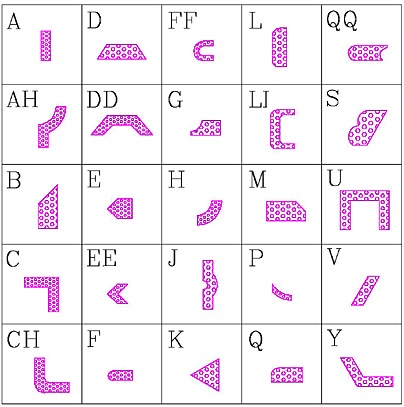

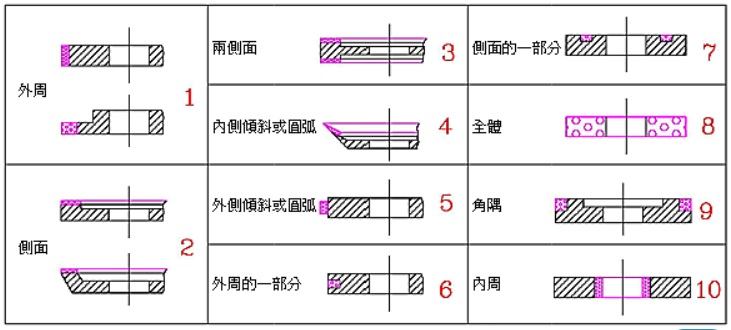

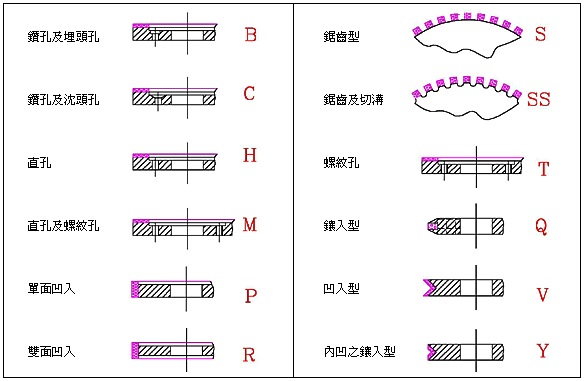

1. Shape of Core Plate

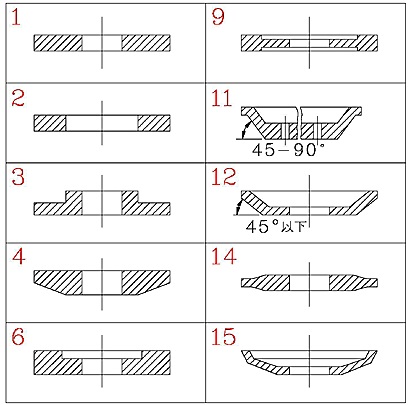

2. The Cross Section of Diamond Layer

3. The Position of Diamond Layer

4. Modification

Notices for Diamond and CBN Wheel

(A)If Diamond and CBN Wheel want to exert fully excellent features, be noticed for the use:

a.Mechanical Part

(1) Precision mandrel

(2) Excellent machine rigidity

(3) Sufficient working horsepower

(4) Suitable wheel speed, crossing speed and in-feed

b.Wheel Installation

(1) Wheel hole and mechanical mandrel are compatible with H6.

(2) The peripheral run-out of wheel within 0.01mm. The surface run-out of wheel within 0.02mm.

(3) True roundness

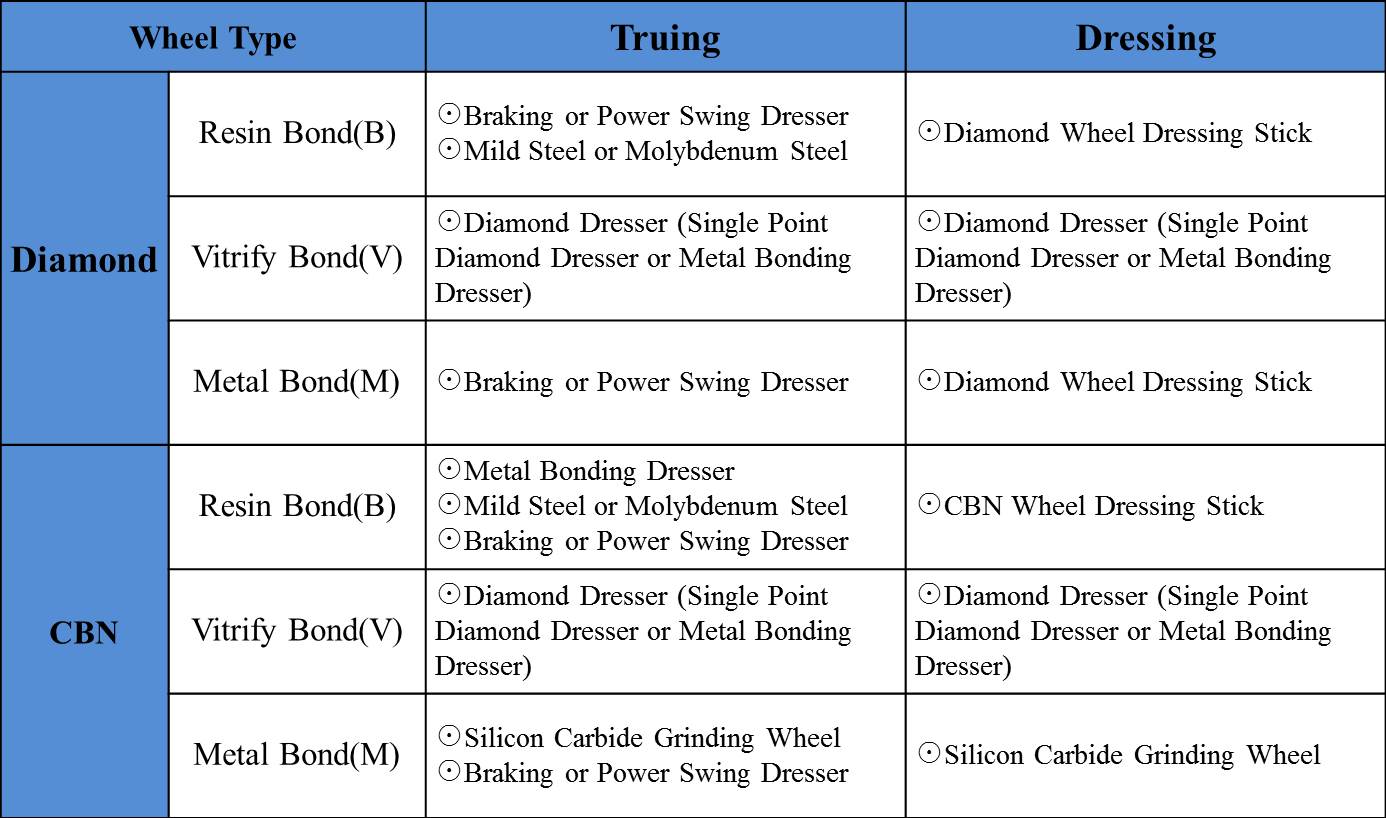

(B)Truing and Dressing

- Truing

To restore concentricity and square the face, or impress upon it some form. - Dressing

Dressing is definitely a treatment of a wheel face to restore or change its cutting action and any truing or sharpening of the face is purely coincidental.

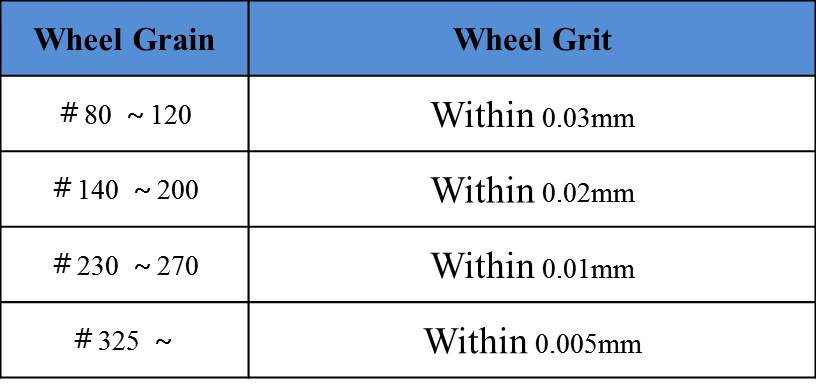

(C)Truing and Dressing Recommendation

(D)Coolant

Wet grinding is adopted within the possible range (If it cannot help, a spray or air will be blew and delivered.) because coolant will have a lot of influence on the roughness of grinding surface, surface precision, wheel sharpness and wheel life.

(E)Ideal In-Feed